A Guide to Mastering The Last Mile Delivery in Singapore 2026

Unlock the secrets of the last mile delivery for your Singapore e-commerce store. Learn proven strategies to reduce costs, improve speed, and delight customers.

Unlock the secrets of the last mile delivery for your Singapore e-commerce store. Learn proven strategies to reduce costs, improve speed, and delight customers.

Think of your entire fulfilment process like a marathon. The last mile delivery is that final, crucial stretch—the part where the race is truly won or lost. It’s the critical journey a package takes from a local hub right to your customer’s hands, and it’s almost always the most expensive and complex part of the entire supply chain.

The last mile is your final touchpoint with the customer and a defining moment for your brand. In Singapore’s dense and demanding e-commerce landscape, this final stage directly shapes customer satisfaction, loyalty, and your store’s reputation.

For anyone selling on platforms like Shopee, Lazada, and TikTok Shop, this final interaction carries immense weight. A delayed parcel or a missed delivery window can quickly turn into a negative review, hurting your store’s rating and turning away future buyers.

It’s easy to overlook just how much this stage costs, but it often represents the single largest expense in the fulfilment process. In Singapore, last mile delivery has grown from a niche function into a critical backbone of the country’s S$9–10 billion e‑commerce economy.

Studies on last mile cost structures consistently show this final leg eats up over 50% of total logistics spend per order, making it the biggest cost driver in fulfilment by a long shot. You can read more in this analysis of Singapore’s last mile delivery market.

This means every bit of efficiency you can find—whether through smarter routing or fewer failed deliveries—translates directly into meaningful cash in your pocket.

Get the last mile right, and you’ve got yourself a powerful advantage. Customers today expect a seamless experience from the moment they click “buy” to the second they unbox their order. This includes speed, accuracy, and clear, honest communication.

Here’s how a strong last mile strategy helps your business:

As a practical example, a seller who consolidates their daily Shopee and Lazada orders for a single courier pickup can often negotiate better rates and slash administrative time. Another actionable insight is to offer click-and-collect options at nearby convenience stores, which dramatically reduces the rate of failed residential deliveries.

The last mile is where your online promise becomes a physical reality for the customer. Getting it right is about delivering on your brand’s commitment to quality and service.

As delivery methods evolve, so do the tools for the job. Many businesses are now exploring more sustainable and efficient vehicles for dense urban routes. By understanding these dynamics, you can transform a complex operational headache into a major business advantage.

While the idea of last mile delivery is the same everywhere, executing it in Singapore presents unique challenges. The island’s intense urban density and high customer expectations create a pressure-cooker environment where even small mistakes can spiral into big costs.

For e-commerce sellers, these are daily headaches that eat into profits and risk customer ratings. For instance, a delivery van stuck in CBD traffic during rush hour is a direct hit to your cost per delivery and a potential one-star review on your Shopee or Lazada store.

One of the biggest and most common frustrations is the first-attempt delivery failure. This is what happens when your driver shows up, but nobody is home to receive the package. The financial hit is instant and painful.

Each failed attempt forces your courier to store the parcel, re-schedule the delivery, and send the driver out all over again. This instantly doubles the delivery cost for that one order, wiping out your profit margin in a flash. In a market this competitive, you can’t just pass that cost on to the customer.

A failed delivery is a financial drain and a customer experience failure rolled into one. The cost of re-delivery, coupled with potential customer frustration, makes first-attempt success a critical KPI for any Singaporean e-commerce business.

It also creates a ripple effect. That single failure disrupts the driver’s entire schedule for the day, delaying every other delivery on their route. To see how a central system can help manage these disruptions, take a look at our guide on warehousing and logistics operations. One missed delivery can easily snowball into a series of service issues.

Singapore’s dense, high-rise population creates one of the highest delivery densities in the world. On mega-sale days like 11.11, it’s not uncommon for drop-off densities to shoot past 150–200 parcels per driver, pushing your operations to the absolute limit. For sellers, this means efficient order batching and tight cut-off times are non-negotiable. You can explore more on these regional trends in this last-mile market analysis.

Here’s a look at some of the key delivery challenges and how they impact your business.

Common Last Mile Challenges and Their Business Impact

| Challenge | Operational Impact | Business Consequence |

|---|---|---|

| Failed First Attempt | Driver must return parcel to hub and re-attempt later, disrupting the entire route. | Doubles delivery cost for the order, erodes profit margins, and risks customer dissatisfaction. |

| Parking Scarcity | Drivers waste minutes circling for legal parking at HDBs or condos, reducing total daily drops. | Increases time per delivery, raises fuel costs, and leads to lower overall driver productivity. |

| Condo Accessibility | Security checks, intercom calls, and specific lift access add significant time to each stop. | Lengthens the delivery window, making it harder to meet same-day or next-day promises. |

| Navigational Complexity | One-way streets, ERP gantries, and restricted zones require careful route planning. | Inefficient routes lead to wasted fuel, potential fines, and longer delivery times. |

| High Customer Expectations | Demand for same-day or next-day delivery shortens every timeline from order to dispatch. | Puts immense pressure on warehouse and logistics teams, leaving no room for error. |

These challenges are daily operational hurdles that directly affect your bottom line and your ability to keep customers happy.

This density brings very specific, practical problems for drivers every single day:

Today’s online shoppers see speed and flexibility as standard. The demand for same-day or next-day delivery is the baseline expectation that puts massive pressure on your entire fulfilment process.

This compresses every timeline, from the moment an order is placed to the final handover. If your warehouse team is slow to pick and pack, or if your courier pickup is missed by just 30 minutes, your promise of next-day delivery is broken.

Successfully managing the last mile delivery in Singapore means building a resilient operation that can absorb these daily shocks. It demands a proactive strategy to navigate traffic, streamline access to residential buildings, and minimise the costly fallout from failed delivery attempts.

You can’t improve what you don’t measure. Once you move past the daily scramble of packing orders and printing labels, the secret to a profitable last-mile operation is tracking the right Key Performance Indicators (KPIs). These numbers tell the real story of your operational health.

Focusing on the right metrics helps you spot small problems before they become big ones, figure out which of your courier partners are actually performing, and make decisions based on data, not guesswork. Without this data, you’re essentially flying blind, unable to see where money is being wasted or where your customer experience is falling apart.

Your On-Time Delivery (OTD) Rate is a direct measure of your promise to your customers. It’s the percentage of orders that arrive within the delivery window you committed to. A consistently high OTD is a powerful signal that your operation is reliable.

Calculating it is straightforward: (Total On-Time Deliveries / Total Deliveries) x 100

In Singapore, an acceptable OTD rate is typically above 95%. If you see your numbers dipping below this, it’s a red flag. As an actionable insight, review if the delays are consistent with a specific courier or region. If one courier is constantly late, it’s time to renegotiate or switch partners for that route.

This is one of the most critical metrics for your profitability. Cost Per Delivery (CPD) tells you exactly how much you spend, on average, to get a single order into a customer’s hands. A common mistake is to only count the courier fee.

To get your true CPD, you have to include all the associated costs:

For example, your courier fee might be S$3.50, but if you spend S$0.50 on packaging and S$1.00 in labour to pack that order, your actual CPD is S$5.00. Understanding this true cost helps you price your products and set your shipping fees accurately to protect your margins.

Your real Cost Per Delivery is the total sum of every expense required to move an item from your shelf to the customer’s doorstep, including the hidden costs of labour and materials.

Taking it a step further, tracking CPD by postal code or district can be incredibly insightful. You might discover that deliveries to certain high-security condos or congested business districts consistently cost more, which allows you to adjust your strategy for those specific areas.

As we’ve discussed, a failed first attempt is a profit killer. The First-Attempt Delivery Success (FADS) Rate measures how often your deliveries are successful on the very first try. A low rate here points directly to inefficiencies and rising costs.

Here’s the calculation: (Number of Successful First Attempts / Total Delivery Attempts) x 100

A strong FADS rate should be well above 90%. If yours is lower, you need to dig into the “why.” Are customers providing incorrect or incomplete addresses? Are the delivery windows unclear? Is your courier not bothering to contact the recipient before arriving?

For instance, a seller noticing a low FADS rate in a specific neighbourhood could roll out a simple, actionable fix. They could start sending an automated SMS to customers in that area on the morning of the delivery, confirming the address and reminding them of the time slot. This small step can make a massive difference to the success rate.

By consistently keeping an eye on these three core metrics, you move from simply managing the last mile delivery to actively optimising it. This data gives you the power to hold your partners accountable, fine-tune your internal processes, and ultimately build a more resilient and profitable e-commerce business.

Knowing your metrics is a great start, but turning that knowledge into action is what separates the businesses that thrive from those that just get by. Improving your last-mile delivery is about putting a series of smart, practical strategies in place that work together to cut costs, speed things up, and make your customers happy.

These are proven tactics designed to give you direct control over your operations, helping you build a more efficient and resilient fulfilment process. Let’s dive into four strategies you can start using today.

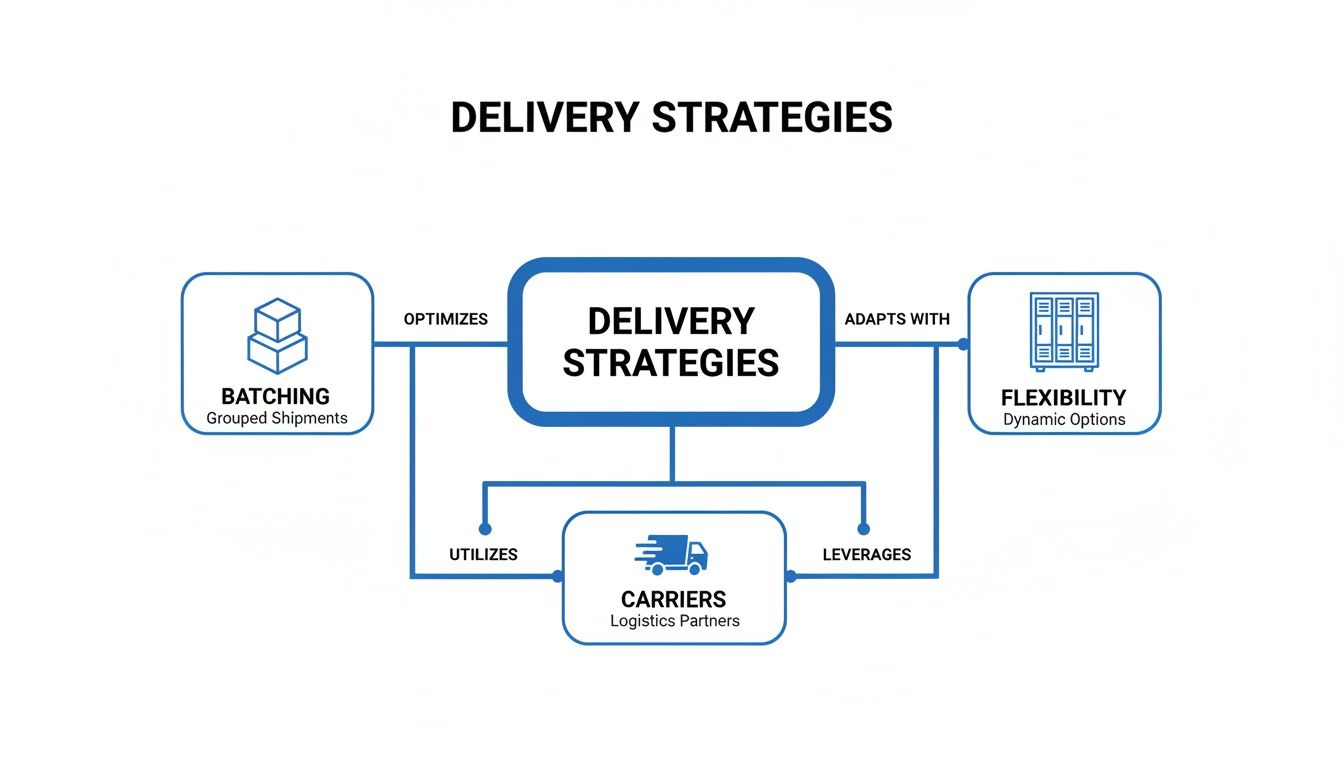

For anyone selling across multiple channels, order batching is one of the most powerful and immediate ways to save time and money. Instead of treating your Shopee, Lazada, and Shopify orders as totally separate workflows, you combine them into a single, unified dispatch process.

This means all orders scheduled for shipment on a given day are picked, packed, and prepped together. When your courier driver shows up, they are making one large, efficient pickup.

This approach pays off in a few key ways:

For example, imagine a business selling on three platforms has 50 orders from Shopee, 30 from Lazada, and 20 from their own website. Instead of arranging three separate pickups, they batch all 100 orders for a single collection with Ninja Van, saving a significant amount of time and likely reducing their overall shipping spend.

Putting all your eggs in one courier’s basket is a risky move. An unexpected service disruption, a sudden price hike, or a dip in performance from your sole provider can bring your entire operation to a standstill. Building a diversified carrier network gives you the flexibility to always choose the best option for every single parcel.

This doesn’t mean you need to work with a dozen different couriers. It’s about strategically partnering with two or three providers who are great at different things.

Think of a flexible carrier network as an insurance policy for your last-mile delivery. When one provider gets bogged down during a peak sales event, you can instantly pivot to another, making sure you keep the delivery promises you made to your customers.

Consider building a network that covers these key bases:

This multi-carrier approach lets you match each order to the most suitable service, balancing cost with delivery speed. For a deeper look into creating this kind of robust system, explore these modern last mile delivery solutions that can help you manage multiple carriers from a single platform.

The traditional model of only delivering to a customer’s home is becoming inefficient, especially in a dense city like Singapore. The high rate of failed first-attempt deliveries is proof that customers aren’t always at home to receive their parcels. Flexible fulfilment options provide convenient alternatives that dramatically boost success rates.

These methods give customers more control over how and when they get their orders, which means a far lower chance of a missed delivery.

Here are some popular options to consider:

Simply offering these choices at checkout is a powerful way to improve your first-attempt delivery rate. It turns a potential delivery failure into a convenient, positive experience for your customer.

Returns are part of e-commerce, but how you handle them has a massive impact on both your bottom line and your customer loyalty. A clunky, expensive, or slow returns process can turn a customer off for good. Reverse logistics is all about managing these returns efficiently and painlessly.

Your goal should be to make the process as easy as possible for the customer while minimising the financial hit to your business. A clear, simple workflow is non-negotiable.

Here’s a practical workflow for handling returns:

By optimising these four key areas—batching, carriers, fulfilment options, and returns—you can build a last-mile delivery operation that is not only cost-effective but also a powerful engine for customer satisfaction and loyalty.

Manual processes are the enemy of growth. Juggling spreadsheets, manually updating stock levels across channels, and copy-pasting tracking numbers is slow and a recipe for costly mistakes that can damage your brand’s reputation. Technology separates a modern, efficient last-mile operation from a chaotic, reactive one.

By adopting the right systems, you can automate repetitive tasks, get a real-time view into your entire workflow, and free up your team to focus on growing the business. These tools are the key to bringing calm and control to your fulfilment process.

At the heart of any efficient e-commerce operation are two critical systems: the Order Management System (OMS) and the Warehouse Management System (WMS). Think of them as the brain and the central nervous system of your fulfilment process.

An Order Management System (OMS) is your command centre for all incoming orders. It pulls in sales from every single channel—Shopee, Lazada, your Shopify store—and organises them into one single, manageable queue. This gives you a clear, unified view of what needs to be picked, packed, and shipped.

A Warehouse Management System (WMS) takes over from there, directing the physical action inside your warehouse. It optimises picking routes so your team isn’t walking unnecessary kilometres, manages inventory locations, and makes sure the right items are packed into the right boxes with speed and accuracy. Many platforms, like OneCart, combine OMS and WMS functions to create a seamless workflow from the moment a customer clicks ‘buy’ to the moment the package is dispatched.

This flowchart shows how technology underpins smart delivery strategies. By batching orders, choosing the right carriers, and offering flexible options, you can build a truly optimised last-mile process.

So, how do all these different systems actually talk to each other? The magic happens through Application Programming Interfaces (APIs). An API acts as a secure bridge, letting different software applications communicate and share data automatically.

Think of an API as a universal translator for your software. It lets your Shopify store instantly tell your inventory system that a product has sold, which then tells your courier partner that a package is ready for pickup—all without a single person having to manually intervene.

This seamless connection is what makes powerful automation possible in the last mile. It’s the behind-the-scenes workhorse that ensures everything stays perfectly in sync. For example, an API connection between your OMS and your courier’s system is what lets you generate hundreds of shipping labels in a single click, a task that would take hours to do by hand.

Integrating these technologies brings real, tangible benefits that you can see in your daily operations and on your bottom line. The goal is simple: automate predictable, time-consuming tasks so your team can handle exceptions and focus on great customer service.

Here are a few practical examples of what this automation looks like:

To make all of this clearer, let’s look at how different pieces of technology solve specific last-mile problems.

This table breaks down some key technologies and shows how they directly address common headaches for e-commerce sellers.

| Technology | Primary Function | Key Benefit for Last Mile |

|---|---|---|

| Route Optimisation Software | Calculates the most efficient delivery routes for multiple stops. | Reduces fuel costs, cuts down on delivery times, and allows drivers to complete more drops per day. |

| Real-Time Tracking (GPS) | Provides live location data for vehicles and packages. | Gives customers accurate ETAs, reduces “Where is my order?” calls, and improves accountability. |

| Electronic Proof of Delivery (ePOD) | Allows drivers to capture signatures or photos on a mobile device. | Eliminates paperwork, instantly confirms delivery, and helps resolve disputes quickly. |

| WMS/OMS Platforms | Centralises order and inventory data from all sales channels. | Ensures accurate picking, prevents stockouts, and streamlines the entire fulfilment workflow from start to finish. |

| API Integrations | Connects different software systems (e.g., OMS to courier). | Automates data sharing, eliminates manual data entry, and ensures all systems are in sync. |

By choosing the right tech for your specific challenges, you can build a powerful, automated system that supports your growth.

More advanced technologies are also becoming much more accessible. Major logistics providers in Singapore, including SingPost, are transitioning to electric vehicle fleets as part of their sustainability initiatives. By putting these systems in place, you build a foundation for growth that is both efficient and reliable.

We get it. Navigating the nitty-gritty of last-mile delivery throws up a lot of practical questions. This section cuts through the noise with direct, clear answers to the most common queries we hear from e-commerce sellers in Singapore. The goal here is to give you actionable insights you can put to work in your business right away.

The smartest way to cut costs is by making your own operations more efficient. The first place to start is order batching.

Consolidating all your daily orders—from Shopee, Lazada, and your own website—into a single pickup with one courier is a powerful move. This instantly increases your shipment volume with that partner, which gives you the leverage to negotiate better rates. It also cleans up your warehouse workflow, cutting down the labour time spent on each order. The time your team saves on packing and dispatch can be just as valuable as the cents saved on courier fees.

Another practical tip is to offer flexible fulfilment options like PUDO points or parcel lockers. It’s often cheaper for couriers to service these centralised locations than individual home addresses, and some partners will pass those savings on to you.

Peak sales events like 11.11 or a post that goes viral on TikTok can flood your system. The key to surviving these surges is preparation and having a scalable system ready to go. Manual processes will absolutely break under this kind of pressure.

This is where an Order Management System (OMS) becomes non-negotiable. It pulls all your incoming orders into one unified queue, stopping the chaos of trying to juggle multiple seller centres at once.

During a sales surge, your biggest bottleneck is your ability to pick, pack, and dispatch quickly. An integrated system that allows for bulk label printing and consolidated picklists is what keeps the operation moving, ensuring you don’t break your delivery promises.

Before any planned sales event, get in touch with your primary courier. Let them know about the expected jump in volume so they can prepare. It’s also a wise move to have a backup courier on standby, just in case your main partner gets overwhelmed.

This really depends on your business model, order volume, and how much you care about controlling the customer experience.

Marketplace-fulfilled services, like Fulfilled by Lazada (FBL), are a decent option for sellers who want to offload the headache of warehousing and shipping. It simplifies your operations, but it comes at a cost and offers very little flexibility.

Self-fulfilling gives you total control over your inventory, packaging, and branding. You can craft a unique unboxing experience and build a direct relationship with your customers. Crucially, it also lets you manage stock for all your sales channels from one central pool, which helps prevent stockouts.

Here’s a quick comparison to help you weigh it up:

Marketplace Fulfilment vs. Self-Fulfilment

| Aspect | Marketplace Fulfilment | Self-Fulfilment |

|---|---|---|

| Control | Low. The marketplace controls packing and shipping. | High. You control branding, packaging, and carrier choice. |

| Complexity | Low. The process is handled for you. | Higher. Requires managing your own warehouse and logistics. |

| Inventory | Inventory is siloed in one channel’s warehouse. | Centralised inventory can serve all sales channels. |

| Branding | Limited. Parcels arrive in marketplace-branded boxes. | Full control over the unboxing experience. |

| Ideal For | New sellers or those with a very limited product range. | Multi-channel sellers who want to build a strong brand identity. |

Many growing businesses start out with marketplace fulfilment and then transition to a self-fulfilment model as they scale. This shift allows them to build a more efficient, brand-centric operation that serves customers across every platform. Choosing the right path is a critical step in mastering the last mile delivery for your brand.

Managing inventory, orders, and shipping across multiple channels doesn’t have to be a tangled mess. OneCart centralises your entire e-commerce operation, giving you a single platform to handle everything from Shopee and Lazada to your own Shopify store. See how you can save time and scale your business at https://www.getonecart.com.

Automate & Scale Your Online Business with OneCart

Start a Free TrialUsed by hundreds of merchants in Singapore & Southeast Asia