Supply Chain Logistics Management Your Essential Guide [2025]

Master supply chain logistics management with this essential guide. Learn proven strategies for inventory, fulfillment, and tech to scale your brand.

Master supply chain logistics management with this essential guide. Learn proven strategies for inventory, fulfillment, and tech to scale your brand.

At its core, supply chain logistics management is the practical process of planning, executing, and controlling how things get from point A to point B. It covers the entire journey of goods, services, and information, starting from the raw material supplier all the way to the end customer.

Put simply, it’s about getting the right product to the right place at the right time—and doing it as efficiently and cost-effectively as possible.

Many people use “supply chain” and “logistics” interchangeably, but they are two distinct concepts that work together. Understanding this difference is the first step toward improving your operations, whether you’re selling on multiple marketplaces or growing a direct-to-consumer (DTC) brand.

Think of it like building a house.

The supply chain is the architect’s master plan for the entire project. It’s the high-level strategy that answers the big questions:

Logistics, on the other hand, is the daily work of the construction crew. It’s the physical, hands-on execution of that master plan. This includes pouring the foundation, framing the walls, and installing the plumbing—the actual movement and management of materials on-site.

You can’t have one without the other. The master plan is useless without the builders to execute it, and the builders are directionless without the plan.

Let’s apply this to a familiar business: your local coffee shop. The supply chain manager designs the entire system to ensure you can always get your favorite latte without a hitch.

The supply chain is the “what” and the “why”—the overall strategy of sourcing, producing, and delivering a product. Logistics is the “how”—the practical, on-the-ground actions that bring that strategy to life.

This strategic thinking involves answering questions like:

Logistics, then, is the series of physical actions that makes this strategy a reality. It’s the journey of every single item. This includes transporting beans from the farm to the roaster, warehousing milk in a temperature-controlled facility, and scheduling the final delivery of paper cups to the cafe’s front door.

For an e-commerce business, this process is nearly identical. To understand how software can streamline these complex operations, you can learn more about the essential role of supply chain management software for your business.

When everything works in harmony, your supply chain logistics management creates a smooth, cost-effective, and reliable flow that directly impacts customer satisfaction and profitability.

Every successful e-commerce business is built on a strong supply chain foundation. Think of it as a building that relies on solid pillars to stay standing. Your online store is no different; it depends on six core functions that must work together seamlessly. Mastering these pillars is the essence of effective supply chain logistics management.

By understanding each pillar, you can identify weak spots in your own operations and pinpoint the best opportunities for improvement. For sellers managing multiple stores on platforms like Shopee, Lazada, and Shopify, a single weakness can disrupt the entire business.

This simple diagram illustrates the journey using a coffee shop as an example, showing how raw materials are transformed into a finished product for a happy customer.

From sourcing the beans to pouring the final cup, every step is a critical link. If one link breaks, the entire operation can grind to a halt.

Let’s break down each of these six pillars. The table below provides a quick snapshot of what each one does and a practical, actionable tip for small or medium-sized businesses.

| Component | Primary Function | Example Action for an SME |

|---|---|---|

| Procurement | Finding and securing the products you sell from reliable suppliers. | Actionable Insight: Identify and build a relationship with a backup supplier for your top-selling product to avoid stockouts during unexpected delays. |

| Inventory | Balancing stock levels to meet customer demand without tying up excess cash. | Actionable Insight: Use your sales data from the last 90 days to set automatic reorder points for key products, preventing both overselling and wasteful overstocking. |

| Warehousing | Storing, organising, and protecting your products before they’re sold. | Actionable Insight: Calculate your total fulfillment cost per order (storage + labor + shipping). Compare this to quotes from two different 3PLs to see if outsourcing is more cost-effective. |

| Transportation | Moving goods from your warehouse to the customer’s doorstep efficiently. | Actionable Insight: Negotiate bulk shipping rates with two different couriers. Use one for fast, local deliveries and the other for more economical cross-country shipments. |

| Order Fulfilment | The “pick, pack, and ship” process that happens after a customer buys. | Actionable Insight: Implement a simple barcode scanning system for picking. This can reduce human errors by over 90% and significantly speed up the packing process. |

| Reverse Logistics | Managing customer returns and exchanges in a smooth, professional manner. | Actionable Insight: Include a pre-printed return label and a simple, one-page instruction guide in every package to make the returns process painless for customers. |

Now, let’s dive a little deeper into what each of these means for your day-to-day operations.

Procurement is how you acquire the products you sell. It’s more than just finding the cheapest supplier; it’s about building strong, reliable partnerships that ensure quality goods are delivered on time, every time.

A smart procurement strategy avoids over-reliance on a single source. For a fashion brand on TikTok Shop, this means having at least two vetted suppliers for your best-selling t-shirt. If your primary supplier faces a production delay, your backup can step in, saving you from stockouts and lost revenue.

Actionable Insight: Schedule quarterly performance reviews with your key suppliers. Discuss their on-time delivery rates, product quality, and communication. This proactive approach helps you identify and solve small issues before they become major problems.

Inventory management is the art of holding just enough stock to meet demand without tying up your cash in slow-moving products. This is especially challenging for multichannel sellers who need a unified, real-time view of inventory across all stores.

Getting this right prevents two critical issues: overselling (disappointing customers) and overstocking (draining cash and wasting space).

A common mistake is investing in a wide range of unproven products. A more effective approach is to focus on a smaller set of bestsellers. Use your sales data to determine when and how much to reorder, keeping your cash flow healthy for marketing and growth initiatives.

Actionable Insight: Use the ABC analysis method. Categorize your products: ‘A’ items are your top 20% of products that generate 80% of revenue, ‘B’ are moderate sellers, and ‘C’ are slow-movers. Focus your management efforts on ‘A’ items to ensure they are never out of stock.

Warehousing covers the physical storage and organization of your inventory. This leads to a crucial decision for every growing business: should you manage your own warehouse (self-fulfilment) or partner with a third-party logistics (3PL) provider?

Actionable Insight: If you’re self-fulfilling, organize your warehouse by sales velocity. Place your best-selling items closest to the packing station to minimize walking time for your team, which can significantly speed up fulfillment. For a deeper dive, explore our comprehensive guide to warehouse inventory management.

Transportation logistics focuses on getting your products from the warehouse to your customer’s doorstep. The goal is to find the perfect balance between cost, speed, and reliability.

For example, an electronics seller shipping from Singapore to Malaysia might use a premium courier with detailed tracking and insurance for high-value items like laptops. For smaller accessories, a more budget-friendly postal service makes better financial sense.

Actionable Insight: Don’t just stick with one shipping service from a single courier. Test different options (e.g., standard vs. express) with your main shipping partners to find the most cost-effective solution for different package sizes and destinations.

Order fulfilment is the operational heart of your e-commerce business. It’s the entire process that begins when a customer clicks “buy”: picking the correct items, packing them securely, and handing them off to the courier.

Speed and accuracy are paramount. A single error—like shipping the wrong size—can lead to a costly return and a negative review.

Actionable Insight: Implement a “scan-to-verify” system at your packing station. Before sealing the box, scan the barcode of each item to ensure it matches the order. This simple check acts as a final quality control step and virtually eliminates packing errors.

Reverse logistics is the process of handling returns and exchanges. A seamless returns process is a powerful tool for building customer trust and encouraging repeat business. Studies show that over 65% of online shoppers check a store’s return policy before making a purchase.

The key is to make it effortless. By providing a clear, simple way for customers to send an item back, you demonstrate that you stand by your products and value their experience.

Actionable Insight: Create a dedicated returns portal on your website where customers can initiate a return and print a shipping label automatically. This not only improves the customer experience but also provides you with valuable data on why products are being returned, helping you identify quality issues.

“If you don’t measure it, you can’t improve it.” This principle is the foundation of effective supply chain logistics management. Instead of guessing what’s working, using Key Performance Indicators (KPIs) provides a clear scorecard, enabling you to make data-driven decisions that directly improve your bottom line.

Focusing on a few vital metrics helps you cut through the noise and see exactly where your processes are strong and where they need attention.

Here are four of the most critical metrics every online seller should monitor. Think of these as a regular health check for your logistics operations.

Knowing your numbers is only the first step. The real value comes from using them to make tangible improvements.

Your logistics KPIs are direct feedback from your business operations. A low Inventory Turnover is your cash flow screaming that it’s trapped in slow-moving stock. A high Cost Per Order is your profit margin signaling that it’s being squeezed.

Let’s use a practical example. Imagine your Inventory Turnover is low. This means you have cash tied up in products that aren’t selling—money that could be used for marketing or stocking up on popular items.

Similarly, if your On-Time Delivery Rate drops, investigate the root cause. Is a specific courier underperforming in a particular region? The data gives you the leverage to discuss the issue with your shipping partner or test an alternative carrier for those routes. Remember, optimizing your logistics often comes down to improving your ability to predict what’s next; you can explore powerful strategies for improving demand forecasting accuracy.

By consistently tracking these KPIs, you move from reacting to problems to proactively building a more efficient and resilient supply chain.

If you’re running a direct-to-consumer (DTC) brand or selling across marketplaces, you know the challenges. The growth potential is huge, but so are the operational headaches—from preventing stockouts during flash sales to meeting ever-increasing customer demands for faster delivery.

There is no single magic solution. Instead, success lies in implementing practical, proven strategies to tackle these common pain points head-on.

One of the biggest challenges for sellers on platforms like Shopify, Lazada, and Shopee is inventory synchronization. When your stock levels aren’t updated in real-time across all channels, you risk overselling—selling an item you no longer have in stock.

This forces you to cancel orders, which creates a negative customer experience and can damage your seller ratings. The only viable solution is a centralized system that serves as a single source of truth for your inventory.

Actionable Insight: Invest in a simple inventory management system that automatically syncs stock levels across all channels in real-time. For example, when an item sells on Lazada, the available quantity is instantly updated on your Shopify and Shopee stores. This automation makes it impossible to oversell, preventing costly mistakes and protecting your brand reputation.

Shipping costs can feel like a constant threat to your profit margins. However, passing these increases directly to customers can lead to cart abandonment. The key is to find a strategic balance.

Instead of viewing shipping as a mere expense, treat it as a strategic tool.

You don’t always have to offer free shipping on every order. A more effective strategy is to set a minimum order threshold to qualify for it (e.g., “Free shipping on orders over $50”). This incentivizes customers to add more items to their cart, which increases your average order value and helps offset the shipping cost.

Actionable Insight: Conduct a packaging audit. For one week, weigh and measure every packed order. Compare the dimensions to the actual product size. You’ll likely find that you’re using oversized boxes, which leads to higher dimensional weight charges. Switching to smaller, right-sized packaging can immediately reduce your shipping fees.

Customer expectations have evolved. Fast delivery is no longer a perk; it’s the standard. While competing with retail giants seems daunting, small and medium-sized businesses can significantly speed up their fulfillment with smart internal processes.

The key is to optimize your warehouse workflow for speed and accuracy.

Actionable Steps for Faster Fulfilment:

Building operational resilience is crucial in a dynamic market like Singapore, which remains a key logistics hub due to its stability and connectivity. For more on this, you can read about Singapore’s logistics sector resilience on cbre.com.sg.

To further protect your operations from sudden demand spikes, use our free safety stock calculator to determine the optimal inventory buffer.

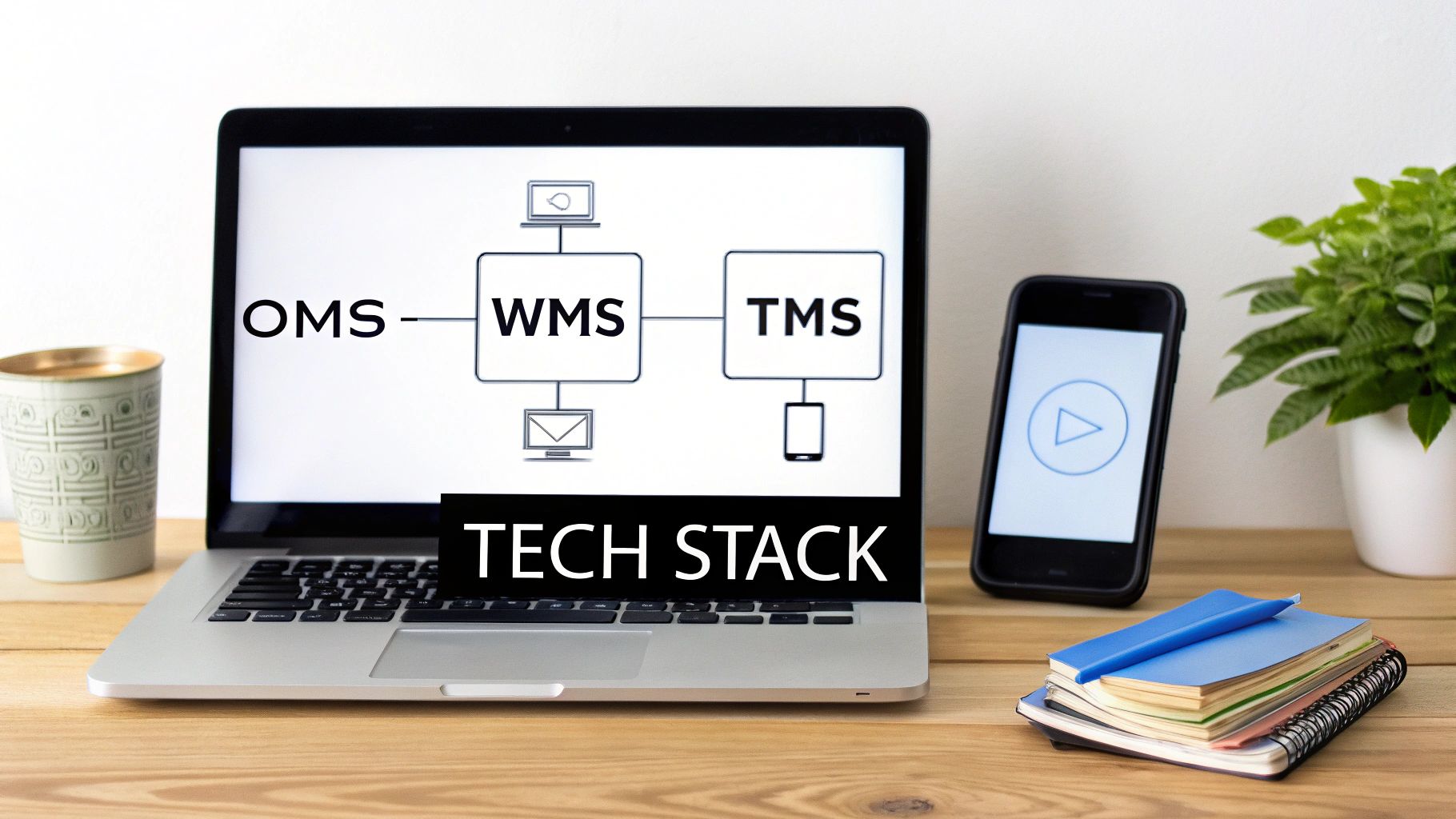

Let’s talk about the engine that runs your e-commerce business: your technology. While a simple spreadsheet might work when you’re handling a few orders a day, it quickly becomes a bottleneck as you grow. The right technology stack automates repetitive tasks, prevents costly errors, and provides a clear, unified view of your entire operation.

Think of your tech stack as the operational team in a busy restaurant. You have a host to manage reservations, a kitchen crew to prepare the food, and a delivery driver to get it to the customer. Each has a specific role, but they must communicate perfectly to ensure a smooth experience.

For any serious e-commerce business, the tech stack is built on three core systems: the Order Management System (OMS), Warehouse Management System (WMS), and Transportation Management System (TMS).

Order Management System (OMS): This is your central command center. An OMS consolidates orders from all your sales channels—Shopify, Lazada, TikTok Shop—into a single dashboard. It manages the entire order lifecycle from purchase to post-delivery.

Warehouse Management System (WMS): This is your warehouse director. A WMS organizes everything inside your warehouse, from tracking inventory locations to optimizing picking routes. Its primary goal is to ensure inventory accuracy and efficient order fulfillment.

Transportation Management System (TMS): This is your shipping coordinator. A TMS takes over once an order is packed. It handles everything from comparing courier rates and printing shipping labels to tracking packages and managing carrier performance.

While you may not need all three systems from day one, understanding their roles helps you plan for scalable growth.

The real power of a tech stack lies in how these systems integrate and share data seamlessly. This behind-the-scenes communication allows for a fully automated, error-free workflow.

Here’s how an order flows through an integrated system:

This entire process can happen in seconds, without any manual data entry. Without integration, each step would require manual work, creating delays and opportunities for human error.

For most sellers, the journey starts with a robust Order Management System, which serves as the central hub connecting sales channels to logistics. To learn more about this foundational tool, read our guide on what an Order Management System is and why your business needs one.

Technology in logistics is advancing rapidly. Singapore’s supply chain sector, for example, is heavily investing in artificial intelligence, with the market projected to grow from US$2.11 billion to US$6.51 billion by 2031. This trend reflects a broader shift towards smart technologies like IoT sensors and RFID, which provide real-time visibility and transform traditional warehouses into intelligent, data-driven hubs.

Choosing the right technology starts with a solid foundation. A system that centralizes your orders and inventory is the most critical first step toward building a scalable and efficient supply chain.

Understanding the theory is one thing, but applying it requires a clear, step-by-step plan. We’ve broken down the process of improving your supply chain logistics management into three practical phases.

Before making changes, you need an honest assessment of your current operations. The goal is to identify hidden bottlenecks, inefficiencies, and manual tasks that are costing you time and money.

Map Your Order Journey: Take a recent order and physically walk through every step it takes, from the moment the customer clicks “buy” to when it’s handed to the courier. Document each touchpoint, noting how long each step takes. This simple exercise will immediately highlight delays and redundant tasks.

Calculate Your Baseline Metrics: Use data from the last 30 days to calculate your current Order Accuracy Rate, On-Time Delivery Rate, and Cost Per Order. These numbers will be your starting point for measuring improvement.

List All Manual Tasks: Create a list of every task that requires manual data entry or copy-pasting. This could be updating stock levels on Shopify after a sale on Lazada or manually typing addresses into a courier portal. These are prime candidates for automation.

With your audit complete, you can now create a targeted improvement plan. This phase is about setting clear, realistic goals and selecting the right tools or partners to help you achieve them.

A plan without a specific goal is just a wish. Define what success looks like first. For example, “Reduce picking and packing errors by 50% within 60 days” or “Cut our average shipping cost by 10% this quarter.”

This is where you put your plan into action. A successful rollout is gradual, includes team training, and focuses on continuous improvement.

Train Your Team: Ensure everyone involved understands the new processes and software. Proper training minimizes confusion and resistance, leading to faster adoption.

Run a Pilot Test: Before a full-scale launch, test your new system or process with a small, manageable batch of orders. This allows you to identify and fix any issues without disrupting your entire operation.

Monitor KPIs and Adjust: Continuously track the metrics you established in Phase 1. Are they improving? Use the data to make ongoing tweaks and refinements to your new workflow. For example, if picking times haven’t improved, you may need to reorganize your warehouse layout.

This structured approach is essential in a rapidly evolving market. For example, Singapore’s freight and logistics market is projected to reach USD 33.33 billion by 2030, driven by the adoption of integrated digital platforms. Following a methodical checklist helps businesses adapt and thrive. For more insights, you can read about Singapore’s premier logistics hub on mordorintelligence.com.

Let’s address some of the most common questions from e-commerce sellers to help you make smarter decisions for your business.

While often used interchangeably, their roles are distinct.

The supply chain is the entire strategic framework. It encompasses everything from sourcing raw materials and supplier relationships to manufacturing and final delivery. It’s the big-picture plan.

Logistics is a component of the supply chain. It refers to the physical execution of that plan—the hands-on work of moving, storing, and managing goods. This includes warehousing, inventory management, shipping, and order fulfillment. In short, logistics is the set of activities that makes the supply chain move.

Moving to a third-party logistics (3PL) partner is a significant step, often triggered by growth. Here are clear signs it might be time:

Reducing shipping costs is a top priority, but it doesn’t have to mean slower service. The most significant savings are often found in operational efficiencies.

A major hidden cost in shipping is dimensional (DIM) weight. Carriers charge based on package size, not just weight. More than half of unnecessary DIM charges come from using boxes that are too large for the products inside. You are literally paying to ship air.

Here are three actionable steps you can take:

Ready to stop overselling and streamline your multichannel operations? With OneCart, you can centralise your inventory, orders, and listings from Shopee, Lazada, Shopify, and more into a single powerful dashboard. Book a demo today and see how you can achieve ROI in days.

Automate & Scale Your Online Business with OneCart

Start a Free TrialUsed by hundreds of merchants in Singapore & Southeast Asia