Small Business Inventory Management: Master Solutions for Profitable Stock [2026]

Boost profits with expert small business inventory management insights, practical systems, metrics, and tools to streamline stock and grow your business.

Boost profits with expert small business inventory management insights, practical systems, metrics, and tools to streamline stock and grow your business.

For most small business owners, “inventory management” sounds like a chore—something you do on a Saturday with a clipboard and a groan. But thinking of it that way is a massive missed opportunity.

Inventory management is the strategic system you use for ordering, storing, and selling everything you stock. Think of it as the central nervous system of your entire retail operation. It connects what your customers want directly to your cash flow, making sure you have the right products in the right place at the right time.

At its heart, inventory management is all about knowing what you have, where it is, and when you need to order more. Getting this right helps you sidestep the two biggest profit killers for any small business: overstocking and stockouts.

Let’s make this practical. Imagine you run a small boutique selling handmade soaps.

If you overstock, you’ve spent a ton of cash on lavender-scented bars that are now just sitting in the back room. That’s dead money—cash tied up in product that could be used for marketing, paying rent, or launching a new scent.

On the flip side, a stockout means that a loyal customer who came in specifically for your popular charcoal soap leaves empty-handed and disappointed. Worse, they’re probably heading straight to your competitor.

Before we dive deeper, here’s a quick cheat sheet of the core concepts we’ll be breaking down. This will give you a solid foundation for everything that follows.

| Concept | What It Is | Why It’s Important for Your Business |

|---|---|---|

| Perpetual vs. Periodic | Two different methods for tracking inventory—either continuously in real-time (perpetual) or at specific intervals (periodic). | Determines how up-to-date your stock counts are, which directly impacts your ability to prevent overselling. |

| Safety Stock | A small, extra buffer of inventory you keep on hand to protect against unexpected spikes in demand or supplier delays. | Acts as your insurance policy against surprise stockouts, keeping customers happy even when things go wrong. |

| Reorder Point | The specific stock level that triggers you to order more of a product. It’s calculated to ensure new stock arrives just before you run out. | Automates your purchasing decisions and prevents last-minute scrambles, ensuring a smooth and continuous supply. |

| Just-in-Time (JIT) | An advanced strategy where you order inventory to arrive exactly when it’s needed for sale, minimizing storage costs. | Frees up significant cash flow by reducing the amount of money tied up in unsold stock sitting in a warehouse. |

| FIFO & LIFO | “First-In, First-Out” and “Last-In, First-Out” are accounting methods for valuing inventory, crucial for perishable or trend-based goods. | Helps you accurately calculate profit margins and minimize waste by ensuring you sell older stock before it expires or goes out of style. |

These are the fundamental tools every successful retailer uses to turn their products into profit.

Mismanaging your stock is a direct hit to your bottom line and your brand’s reputation. Without a clear system in place, you’re making expensive guesses about what your customers want.

This is a bigger problem than most owners think. The average retailer reports an inventory accuracy of just 70%. That gap is staggering. It means for every 100 items you think you have, 30 might be miscounted, lost, or damaged.

That inaccuracy leads directly to lost sales. In fact, 82% of in-store shoppers said they ran into out-of-stock items in the last year, a frustration that sends them right to the competition. For a closer look at the numbers, you can explore more data about retail inventory management to see the full picture.

Actionable Insight: Good inventory management is a powerful competitive advantage. It turns your products into a well-oiled machine that generates cash, instead of a warehouse full of stagnant capital.

Whether you sell from a single brick-and-mortar shop, an online store, or across multiple channels, a solid inventory strategy is non-negotiable for growth.

This becomes especially critical for anyone selling on multiple platforms like Shopee, Lazada, and Shopify. Manually trying to update stock levels across every channel is a recipe for disaster. It almost always leads to overselling—selling an item on one marketplace that has already sold out on another, forcing you to cancel orders and damage customer trust.

A well-organized system brings immediate, tangible benefits:

Ultimately, mastering your inventory transforms a daily headache into one of your most powerful tools for building a profitable and sustainable business.

Picking the right way to track and value your stock is the bedrock of good inventory management. These systems are how you’ll count what you have, figure out which products matter most, and ultimately, calculate how profitable you really are. Without a solid method, you’re just guessing—and that’s a risky way to run a business.

The two main ways to track inventory are known as periodic and perpetual.

A local bakery might do a periodic count once a week, physically tallying up every croissant and loaf of bread on the shelves. It’s simple, but it only gives you a snapshot at that exact moment.

An electronics store, on the other hand, absolutely needs a perpetual system. Every single time a smartphone is sold—whether it’s online or in the shop—the inventory count updates instantly. This live data is critical for preventing overselling, especially when you’re managing multiple sales channels. To keep track of every item leaving your stock, a flawless itemized receipt template for each sale is a great way to ensure accuracy.

Beyond just counting, a few proven techniques can help you manage your stock more intelligently, cutting costs and boosting sales. These methods give you a framework for making smarter decisions about what to buy and when to sell it.

Actionable Insight: Using these methods helps you shift from just reacting to your stock levels to proactively controlling them. You start making strategic choices that directly impact your cash flow, cut down on waste, and make sure you can meet customer demand without overspending.

Not all of your inventory is created equal. ABC analysis is a powerful technique that helps you sort your products based on their value to your business, so you can focus your time and energy where it truly counts.

Think of it as sorting all your products into three buckets:

A small online boutique, for example, would use ABC analysis to identify its best-selling dresses as A-items, making sure they are always in stock. Seasonal accessories might be B-items, while low-margin basics like socks would be C-items.

Getting this mix wrong can put a serious strain on your finances. Globally, small and medium-sized businesses are drowning in excess stock. In fact, 17% report that over 10% of their inventory is “dead stock”—unsold for a year or more. This idle inventory can tie up 20-60% of a company’s total capital, a crippling problem in any economy.

For a deeper look into real-time tracking, you can check out our guide on the perpetual inventory system.

Once you have your core inventory methods in place, the real work begins: measuring what’s actually working. You can’t improve what you don’t measure. This is where Key Performance Indicators (KPIs) come in. Think of them as simple calculations that give you a clear, data-backed view of your inventory’s financial health.

KPIs are like the dashboard of your business. Just like a driver checks the fuel gauge and speedometer, you need to check your inventory metrics to know if you’re on track for profitability or heading toward costly problems like dead stock. Tracking these numbers helps you move from guesswork to smart, strategic decisions that directly boost your bottom line.

One of the most powerful metrics you can track is the Inventory Turnover Ratio. This number tells you how many times your business sold and replaced its entire stock over a specific period, usually a year. It’s a direct measure of how efficiently you’re moving products.

A high turnover ratio generally means products are flying off the shelves, which is fantastic for cash flow. On the flip side, a ratio that’s too high could be a red flag. It might mean you’re understocking and leaving money on the table by missing out on sales.

Here’s the simple formula: Inventory Turnover Ratio = Cost of Goods Sold (COGS) / Average Inventory

Practical Example: A small online store’s COGS for the year was $50,000. Their inventory was worth $12,000 at the start of the year and $8,000 at the end.

- Calculate Average Inventory: ($12,000 + $8,000) / 2 = $10,000

- Calculate Turnover Ratio: $50,000 / $10,000 = 5

This tells them they sold and replenished their entire inventory 5 times over the year—a solid, healthy number for many retail businesses. To get a more detailed breakdown, you can learn more about the inventory turnover formula and how to use it.

While turnover gives you a big-picture view, the Sell-Through Rate zooms in on the performance of specific products. It measures the percentage of inventory you’ve sold within a set time (usually a month) compared to what you originally received from your supplier.

This metric is incredibly useful for judging the success of a new product launch, a marketing campaign, or your performance during a holiday season. It answers the crucial question: “How well did that new product line actually sell?”

The formula is straightforward: Sell-Through Rate = (Units Sold / Units Received) x 100

Practical Example: A clothing boutique orders 100 units of a new seasonal dress. In the first month, they sell 75 of them.

Calculate Sell-Through Rate: (75 / 100) x 100 = 75%

A 75% sell-through rate is excellent. It shows strong customer demand. But if the rate were closer to 20%, it would be a clear signal that the dress isn’t resonating, and it might be time to mark it down to move the remaining stock.

Finally, let’s talk about the metric that ties it all back to profit: Gross Margin Return on Investment (GMROI). This KPI tells you exactly how much profit you’re making for every single dollar you invest in inventory. It answers the most important question: is your stock a true asset or a financial drain?

A GMROI greater than 1 means you’re selling goods for more than they cost you, which is exactly where you want to be.

The formula is: GMROI = Gross Profit / Average Inventory Cost

A higher GMROI indicates that you’re pricing your products well and managing your inventory costs effectively. Think of it as the ultimate report card for your small business inventory management strategy, confirming that all your buying and selling efforts are actually paying off.

Moving from a messy stockroom to a proper inventory system can feel like a massive job, but you can manage it by breaking it down into a few clear steps. This is your blueprint for building a system from scratch—one that cuts down on errors, saves you time, and gets your business ready to grow.

Think of this process less like a chore and more like laying the foundation for a calmer, more profitable operation. Each step builds on the last, creating a logical flow that puts you in control of your stock from day one.

Let’s walk through it.

Before you can manage what you have, you need to know exactly what you have. This means a full physical count of every single item you own, from the shop floor to the darkest corner of your backroom. This first count becomes your baseline, your single source of truth.

This part is time-consuming, but don’t cut corners here. An inaccurate start will throw off your entire system down the line.

This is the essential first move in taking back control of your small business inventory management.

With an accurate count in hand, the next big decision is how you’ll track everything going forward. For most small businesses, it boils down to two options: manual spreadsheets or dedicated inventory management software. Studies show that 43% of small businesses don’t track their inventory at all—a huge risk that leads directly to lost sales and wasted cash.

The right tool for you depends on how complex your business is, your sales volume, and where you see yourself in a year or two.

A spreadsheet might feel fine when you’re just starting out, but it quickly becomes a major headache as you grow, especially if you sell across multiple channels like your own website, Shopee, and Lazada. Juggling manual updates is a recipe for overselling.

Here’s a quick comparison to help you decide when it’s time to make the leap.

| Feature | Manual Spreadsheets | Automated Software |

|---|---|---|

| Cost | Free or low-cost (e.g., Google Sheets, Excel). | Monthly or annual subscription fee. |

| Real-Time Syncing | Impossible. Requires constant manual updates across all sales channels. | Instant. Automatically syncs stock levels across all platforms when a sale is made. |

| Error Potential | Extremely high. Prone to typos, formula errors, and outdated information. | Very low. Automates data entry and calculations, minimizing human error. |

| Scalability | Poor. Becomes unmanageable with more products or sales channels. | Excellent. Designed to handle growth, high order volumes, and complex catalogs. |

| Reporting | Basic. Requires manual creation of charts and analysis. | Advanced. Generates detailed sales, profit, and inventory reports automatically. |

While a free tool is tempting, the hidden cost of manual work and errors often outweighs the software subscription fee once you start getting consistent orders.

A Stock Keeping Unit (SKU) is just a unique code you give to each product so you can tell it apart from everything else. A good SKU system is logical and descriptive, telling you and your team key details—like style, color, and size—just by looking at the code.

For instance, a t-shirt could have the SKU: TS-BLU-LG

This simple, human-readable format is way more effective than a random string of numbers. It makes finding products, processing returns, and looking at sales data much faster and less likely to cause mistakes. Just create a consistent format and stick to it for every product you carry.

How you arrange your storeroom has a direct impact on how fast you can pack and ship orders. A chaotic space means slow fulfillment, frustrated staff, and unhappy customers. The goal is to create a logical layout where your most popular items are the easiest to grab.

Think about how you can make the picking and packing process as smooth as possible. Even looking at highly organized sectors, like those using hospital modular storage management systems, can spark ideas for making the most of your space and improving accessibility.

Actionable Insight: Apply the ABC analysis we talked about earlier to your physical layout. Put your “A-Items”—your bestsellers—in the most accessible spot, right next to your packing station. Your slow-moving “C-Items” can go on the higher shelves or in the back.

Finally, it’s time to take the guesswork out of ordering new stock by setting reorder points. A reorder point is the minimum stock level an item can hit before you place a new order. Calculating this stops you from running out of a popular item while you’re waiting for the next shipment to arrive.

The basic formula is pretty simple: (Average Daily Sales x Supplier Lead Time in Days) + Safety Stock = Reorder Point

Let’s say you sell 5 units of a product per day, your supplier takes 10 days to deliver, and you like to keep 20 units as a safety buffer. Your reorder point would be 70.

(5 units/day x 10 days) + 20 units = 70 units

When your inventory for that item drops to 70 units, that’s your automatic signal to order more. This data-driven approach removes emotion from your purchasing decisions, ensuring you always have enough stock without tying up too much cash in products that are just sitting there.

Selling your products on multiple platforms like Shopee, Lazada, TikTok Shop, and your own website is a fantastic way to reach more customers. But it also opens the door to a massive headache for your small business inventory management: keeping your stock levels accurate across every single channel, all at once.

When you manage each storefront separately, you’re creating dangerous delays. Imagine you have only one of a popular item left. A customer buys it on your website, but before you can manually update your Lazada store, another customer buys the exact same item there.

This is the classic nightmare scenario of overselling. You’re forced to cancel one of the orders, which almost always leads to a frustrated customer, a negative review, and maybe even a penalty from the marketplace. Just like that, a single mistake chips away at the trust you’ve worked so hard to build.

Relying on manual updates is like trying to direct traffic at a busy intersection with just a notepad and pen. It’s slow, stressful, and mistakes are practically guaranteed. Every single sale requires you to log into each of your other seller accounts to adjust the stock count—a process that can take precious minutes, or even hours if you get swamped.

In e-commerce, minutes matter. That lag between a sale happening and your inventory getting updated is a window of risk where another customer can buy an item you no longer have. The manual approach simply can’t keep up with the speed of online sales, especially during a flash sale or holiday promotion.

The only real solution is to create a single source of truth for your entire inventory—a central system where one sale, on any channel, updates your stock everywhere instantly.

A centralized inventory system acts as the brain for your entire operation, connecting all your sales channels into one unified dashboard. Instead of having your inventory data scattered across different platforms, it’s all managed from a single command center. This creates a simple, powerful workflow that slams the door shut on overselling.

Here’s a practical example of how it works in real-time:

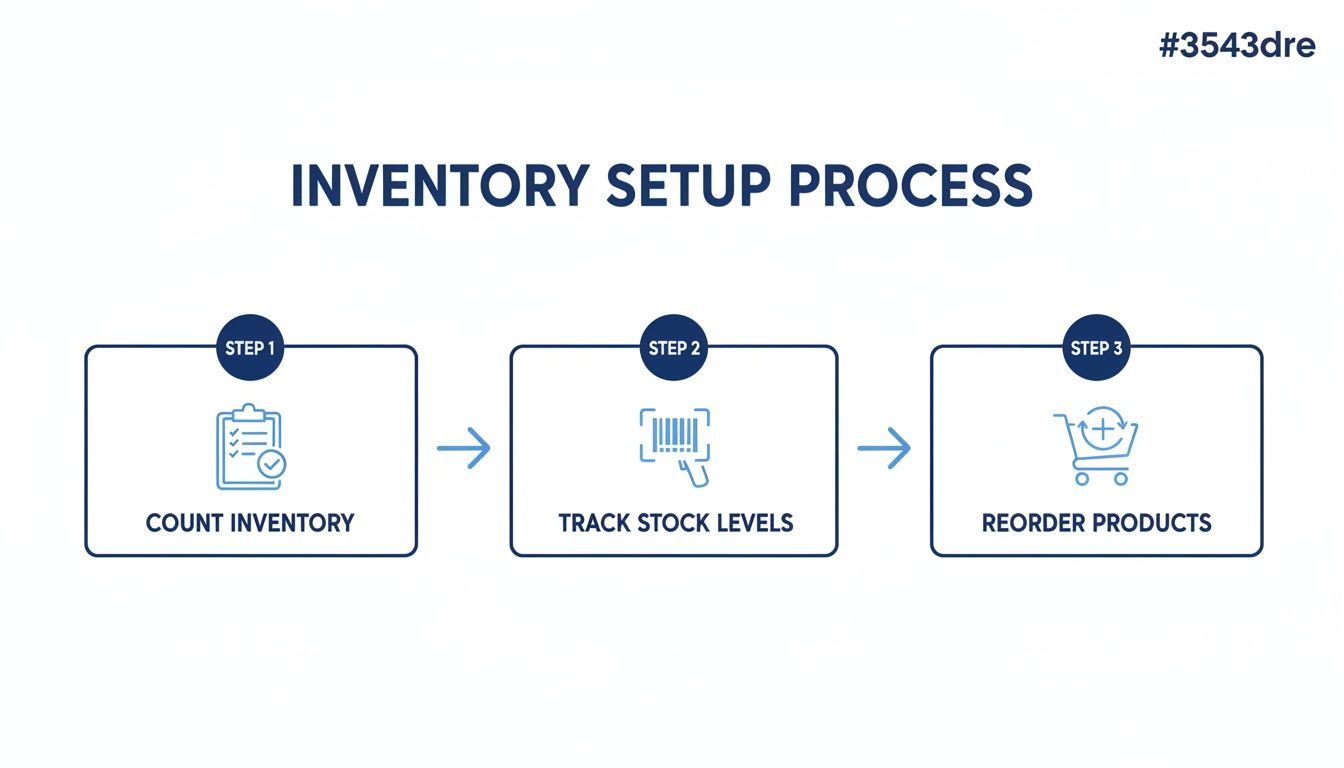

This seamless process ensures that a sale on one platform immediately makes that same stock unavailable everywhere else. This infographic shows the basic flow that a well-managed inventory system automates.

The diagram breaks down inventory control into its core actions—counting, tracking, and reordering. Automation handles these steps flawlessly to maintain perfect accuracy across all your sales channels.

Actionable Insight: By automating this process, you effectively close that window of risk. Your stock levels are always accurate and up-to-date, giving you the confidence to sell aggressively on multiple channels without the fear of disappointing customers. This is how you scale your operations without the chaos.

As your business takes off, the manual methods that once kept you organised can quickly become your biggest bottleneck. The goal is to proactively plan for what you’ll need tomorrow.

This is where automation comes in. It transforms your small business inventory management from a daily chore into a powerful engine for growth.

Think about building a system that can handle thousands of orders without the chaos. It all starts by connecting your core business tools. When your inventory software syncs up with your accounting system, for instance, it automatically updates your cost of goods sold (COGS) with every sale. This gives you a real-time view of your profitability without ever having to touch a spreadsheet.

Suddenly, you’re freed up from tedious tasks and can actually focus on strategy.

The most valuable asset you have for scaling your business is your own sales data. Instead of guessing what to order, automation tools dig into your sales history to forecast future demand. This data-driven approach helps you prepare for seasonal peaks and avoid getting caught off-guard by a sudden surge in a product’s popularity.

AI-powered tools take this a step further by spotting subtle trends and patterns that are nearly impossible for a human to catch. They can analyze market shifts and predict what your customers will want to buy next month, or even next quarter, letting you stock up on the right products at the right time.

Actionable Insight: By using predictive analytics, you turn your sales history into a roadmap for the future. This reduces the risk of overstocking on slow-moving items and ensures your bestsellers are always available, directly protecting your cash flow and customer loyalty.

As you scale, you can also start bringing in more advanced strategies that rely on solid supplier relationships and seamless data sharing. One powerful method gaining traction is Vendor-Managed Inventory (VMI).

With VMI, you essentially give your suppliers a window into your inventory data, allowing them to proactively manage your stock levels for you. This collaborative approach means you always have what you need without having to place the orders yourself. The rise of strategies like this is significant for small businesses.

VMI adoption has surged from 29% to 44%, while consignment models have also climbed. These approaches help marketplace sellers avoid the 17% dead stock trap and prevent painful inventory mismatches. Better yet, using AI for forecasting can slice logistics costs by 15%.

Ultimately, automation is about building a foundation strong enough to support your ambition. Platforms that provide excellent inventory software in Singapore can centralise all these functions, turning complex operations into a smooth, scalable process that just works.

When you’re diving into inventory management, it’s normal for a few specific questions to pop up. Let’s tackle some of the most common ones we hear from small business owners.

The most reliable approach is what’s known as the “freeze and count” method. You need to schedule a specific time when absolutely no sales or deliveries are happening. This effectively freezes your inventory in place, ensuring you’re not trying to hit a moving target.

For example, a retail shop might close for a few hours on a Sunday morning to get it done right. Work in teams of two—one person counts the items on the shelf, and the second person records that number on a sheet or tablet. This simple double-check system drastically cuts down on errors and gives you a solid, reliable baseline to build on.

While a full, wall-to-wall physical count is a massive job you might only do once a year, you should absolutely be doing cycle counting. This just means counting small, specific sections of your inventory on a daily or weekly basis. It’s far less disruptive and keeps your numbers tight all year round.

This is the perfect place to put your ABC analysis into action. Count your high-value “A-Items” more often, maybe even weekly, since any mistakes there hit your finances the hardest. Your slower-moving “C-Items,” on the other hand, might only need a check-in every quarter.

Honestly, a spreadsheet can work—but only if you’re just starting out with a handful of products and selling on a single channel. The minute your business starts to grow, spreadsheets become a huge liability. The biggest risks are human error and the complete lack of real-time syncing.

Picture this: you sell on your own website and a marketplace like Shopee. An item sells on your site. Now you have to manually update your spreadsheet, then remember to log in to Shopee and change the stock level there, too. A single delay or forgotten update can lead directly to overselling, which is a fast way to damage customer trust.

Actionable Insight: Spreadsheets are a starting point, not a long-term solution. The moment you start selling on more than one channel or find yourself spending hours on manual updates, it’s time to upgrade to automated software. It’s a small investment that prevents much larger, more expensive problems down the line.

Ready to eliminate overselling and reclaim hours of manual work? OneCart centralizes your inventory across Shopee, Lazada, Shopify, and more, syncing stock in seconds to give you a single, accurate view of your entire operation. Start scaling your business with confidence.

Automate & Scale Your Online Business with OneCart

Start a Free TrialUsed by hundreds of merchants in Singapore & Southeast Asia