Mastering the Safety Stock Formula to Prevent Stockouts [2026]

Learn how to use the safety stock formula to prevent stockouts and cut costs. Our guide offers step-by-step calculations for ecommerce sellers on any platform.

Learn how to use the safety stock formula to prevent stockouts and cut costs. Our guide offers step-by-step calculations for ecommerce sellers on any platform.

The safety stock formula helps you determine the extra inventory you need to keep on hand to avoid stockouts. A common method is (Maximum Daily Sales × Maximum Lead Time) – (Average Daily Sales × Average Lead Time). This isn’t just theory; it’s a practical calculation that provides a data-backed buffer to protect your sales and maintain customer satisfaction.

Think of your safety stock as the reserve fuel tank for your online store. It’s that extra stash of inventory you hold, not for regular sales, but to protect your business when things don’t go according to plan. This is a critical tool for survival and growth in the competitive world of ecommerce.

This strategic buffer is your main line of defense against two major challenges for any seller:

Without this buffer, you are vulnerable to stocking out of your most popular products. For sellers on marketplaces like Shopee and Lazada, a stockout means more than just a lost sale. It can lead to negative reviews, a drop in your seller rating, and losing visibility in search results.

Finding the right balance is essential. Too little safety stock leaves you exposed to stockouts, which leads to disappointed customers and lost revenue.

However, holding too much inventory is also risky. It ties up your cash, increases storage costs, and heightens the risk of products becoming obsolete, damaged, or expiring on the shelf. This is a common challenge for online sellers.

Actionable Insight: A well-calculated safety stock ensures you can consistently meet customer demand and maintain a strong reputation. It turns a potential inventory crisis into a seamless customer experience.

Getting this right is a core part of effective inventory management best practices that keep your stock levels lean but effective, preventing costly overselling.

When you’re just starting out, it’s tempting to rely on intuition. You might keep “a few extra weeks” of stock on hand and hope for the best. This approach may work for a short time, but as your business grows, it becomes a high-stakes gamble.

A single unexpected supplier delay could exhaust your entire buffer, leading to days or even weeks of lost sales while you scramble to restock.

The solution is to stop guessing and start calculating. Using a safety stock formula transforms your inventory planning from a reactive process into a proactive strategy. It lets you build a precise buffer based on your actual sales data and supplier performance, ensuring you have enough stock to thrive. To learn more about the fundamentals, you can check out our guide on understanding safety stock and how it prevents stockouts.

If you’re ready to move beyond inventory guesswork, the best place to start is with the most widely used safety stock formula. This classic method provides a reliable, data-driven way to build a buffer that protects your business from unexpected sales spikes and supplier delays.

This formula calculates the difference between your worst-case scenario and your normal, everyday operations. The gap between those two is the exact amount of extra inventory you should keep on hand.

The formula is straightforward: (Maximum Daily Sales × Maximum Lead Time) – (Average Daily Sales × Average Lead Time).

Let’s unpack what each piece means and where you can find these numbers in your business data.

By subtracting your average business operations from your worst-case scenario, the formula gives you the exact number of units needed to cover that risk.

Let’s apply this. Imagine you sell a popular skincare product on both Shopee and Lazada and need to determine its safety stock.

After reviewing your sales and shipping data from the past three months, you find:

Now, let’s plug these numbers into the formula:

(120 units × 10 days) – (100 units × 7 days) 1,200 – 700 = 500 units

The result indicates you should hold 500 units of this product as your safety stock. This buffer ensures that if you experience another massive sales day while a shipment is delayed, you won’t stock out and can continue to fulfill orders.

Actionable Insight: Regularly update the inputs for this formula, especially after major sales events or if you notice changes in supplier reliability. Using data that is 6 months or older can give you a misleading safety stock level.

This basic approach became a cornerstone for e-commerce sellers in the early 2000s when marketplaces first exploded, forcing them to manage unpredictable demand. Its value was proven during events like China’s 2011 Singles’ Day, where sales surged beyond anyone’s forecasts. More recently, sellers using this simple formula were better prepared for pandemic-related supply chain chaos, with some studies showing they cut overselling incidents by up to 40%.

You can explore more on how this kind of planning keeps supply chains running in this detailed ASCM overview of safety stock strategies. This method is your first step toward building a more resilient inventory system.

When your sales data is inconsistent, the basic safety stock formula may not be sufficient. An influencer promotion or a flash sale can quickly deplete your inventory. In such cases, you need a more precise layer of protection.

For businesses with unpredictable sales, a more suitable safety stock formula uses statistics to account for that variability: Safety Stock = Z × σD × √L. This formula provides an intelligent buffer that is prepared for unexpected sales surges. Let’s break down what each part means.

This approach helps you move from reacting to past sales spikes to proactively planning for what is statistically likely to happen.

Here’s the breakdown of each component:

Deciding on your service level is a strategic business decision. A higher service level keeps customers happy but also means tying up more cash in safety stock. A 95% service level is a common and solid starting point for most products.

You can also set different levels for different items—perhaps 99% for your best-sellers and 85% for your slower-moving products.

Once you’ve chosen a service level, find its matching Z-score using a standard reference table.

| Service Level | Z-Score |

|---|---|

| 90% | 1.28 |

| 95% | 1.65 |

| 98% | 2.05 |

| 99% | 2.33 |

For a 95% service level, your Z-score is 1.65. This tells the formula you want to be prepared to cover 95% of all expected demand fluctuations.

This statistical safety stock formula revolutionized inventory precision when it was popularized in supply chain courses. Its power was demonstrated during events like the 2018 Black Friday, where global e-commerce sales hit $124 billion, but demand variability spiked 35%. Businesses using this method saw 28% fewer stockouts compared to those using basic formulas. Learn more from the research on statistical safety stock modeling.

Let’s apply this formula. Imagine a DTC brand that sells on WooCommerce and is using OneCart to expand its operations to Lazada. Their data shows the following:

Now, we plug these values into the safety stock formula:

Safety Stock = 1.65 × 200 × √4 Safety Stock = 1.65 × 200 × 2 Safety Stock = 660 units

The brand should aim to keep 660 units on hand as its safety buffer. This calculation ensures they are protected against their typical sales volatility over the 4-week replenishment window, preventing costly stockouts as they expand across multiple channels. Getting this right is a cornerstone of any solid demand planning and forecasting strategy.

The formulas we’ve covered are effective when your main issue is either unpredictable customer demand or unreliable suppliers. But what happens when you face both at once? A flash sale on Lazada might go viral the same week your shipment gets stuck in customs.

Such a combination of events can deplete a simple safety buffer quickly.

For these common scenarios, you need a more robust safety stock formula that accounts for volatility on both the demand and supply sides. This calculation protects you from the disruptions that can halt a growing e-commerce business.

The formula designed for this combined risk is:

Safety Stock = Z × √[(σD² × L) + (μD² × σL²)]

This formula statistically combines the risk of demand swings with the risk of lead time delays. The result is a single, optimized buffer that’s more efficient than calculating two separate safety stock numbers and adding them together.

Let’s break down the variables:

This comprehensive formula gained traction after major global disruptions, like the 2011 Japan tsunami, which caused lead times to jump 40% worldwide. E-commerce businesses using it were able to recover an estimated 25% faster. You can read more about the statistical efficiency of advanced safety stock calculations.

Using this formula is a strategic decision, not necessary for every product. It’s time to upgrade when your business consistently deals with volatility from both ends of the supply chain.

Consider using it if:

This formula offers optimal buffering by statistically combining risks. Recent events, like the Red Sea disruptions that inflated lead times by up to 50%, underscore its value. Internal benchmarks show that Lazada and TikTok sellers using OneCart to apply this method saw 33% fewer stockouts compared to those relying on simpler, static buffers.

Let’s apply this to a real-world scenario. Imagine you’re the warehouse manager for an electronics brand preparing for the 11.11 sales event. Your priority is setting the right safety stock for your best-selling wireless earbuds.

After pulling data from your Shopify and Shopee stores, you have your numbers:

Now, let’s plug these into the formula:

Safety Stock = 1.65 × √[(50² × 14) + (200² × 3²)] Safety Stock = 1.65 × √[(2,500 × 14) + (40,000 × 9)] Safety Stock = 1.65 × √[35,000 + 360,000] Safety Stock = 1.65 × √395,000 Safety Stock = 1.65 × 628.5 Safety Stock ≈ 1,037 units

The calculation indicates you should hold 1,037 units as a safety buffer. This data-backed number gives you the confidence to handle both a sudden pre-sale demand surge and an unexpected supplier delay. You are now prepared to capitalize on the 11.11 peak without the fear of stocking out.

A safety stock formula is only as effective as the data you use. Using inaccurate or outdated numbers will give you a precise but incorrect answer.

Getting the inputs right is the most critical step in applying these formulas for real-world inventory protection.

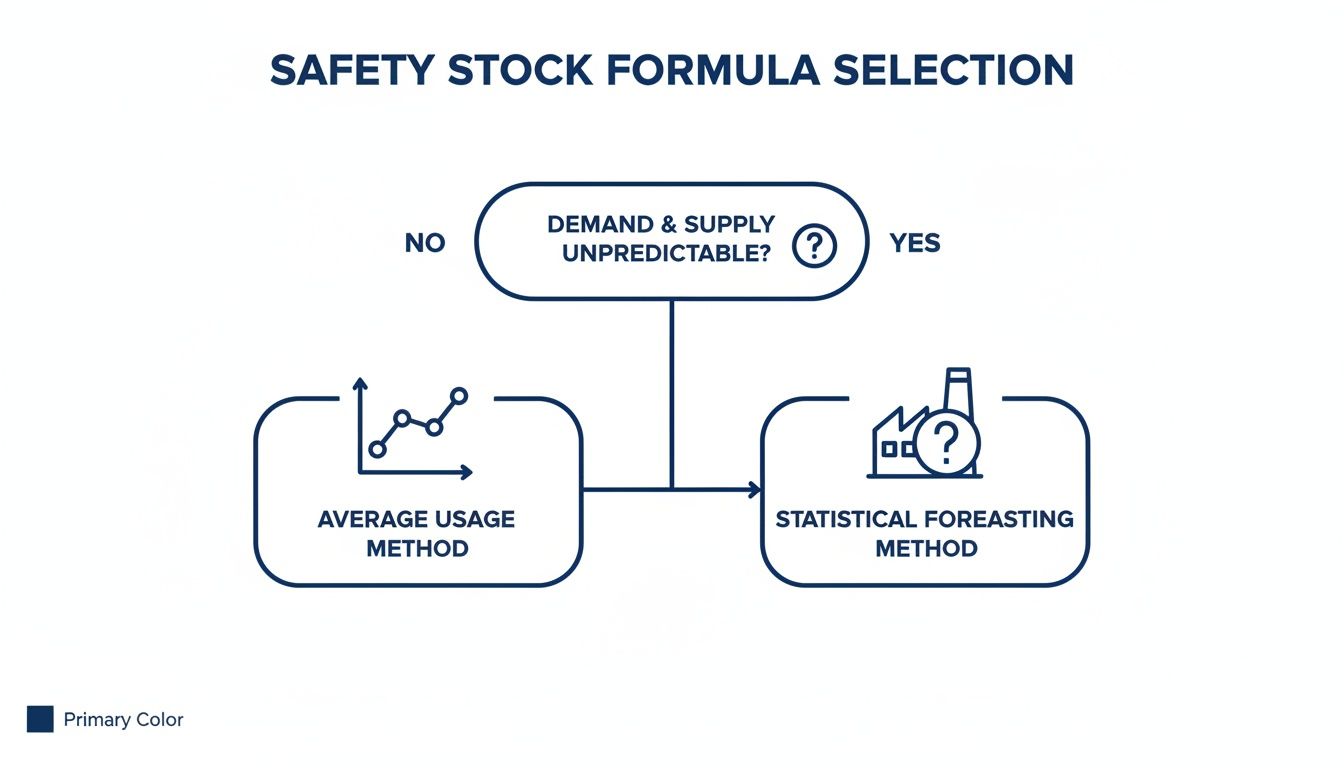

This visual guide can help you decide which safety stock formula best fits your business.

The flowchart shows a simple rule: if your demand and supply are predictable, a basic formula often works. But when you face uncertainty in either area, a more advanced statistical approach is needed to keep your inventory healthy.

Your service level is a strategic decision that balances customer satisfaction with inventory costs. A higher service level reduces the chance of stocking out but also ties up more cash. There’s no single “correct” service level for every product.

A smart approach is to segment your inventory:

Lead time is more than just shipping time. To get an accurate calculation, you need to measure the entire replenishment window.

Lead time begins when you send a purchase order to your supplier and ends when the goods are received, checked in, and available for sale in your inventory system.

To get this right, track the full cycle for your last 5-10 shipments for a specific product and calculate the average. Be honest about internal delays, like the time it takes your team to unpack and process incoming stock. Those days count.

Demand variability is measured using standard deviation. This shows how much your daily or weekly sales tend to deviate from the average. You can calculate it easily with your own sales data.

Here’s a quick way to calculate it in a spreadsheet:

=STDEV.P() and select all your daily sales data.The resulting number is your standard deviation of demand (σD). This input makes your safety stock formula responsive to your product’s actual sales volatility, providing a customized buffer for your business.

Calculating your safety stock is the first step. The next is to move from a spreadsheet to an automated system. Manually updating stock levels is prone to errors and time-consuming. Automation transforms your safety stock formula into an active defense system that works around the clock to prevent overselling.

Think of automation as a 24/7 inventory watchdog. It connects your calculations to your live inventory, automatically preserving your safety buffer across all sales channels. This ensures the protection you’ve calculated is always active.

The core of this automation is a simple rule: your safety stock level becomes the “zero” point for your available inventory.

For example, if you have 100 units of a product and have set a safety stock of 20 units, your inventory system will automatically show only 80 units as available to sell. The remaining 20 are hidden, acting as your emergency buffer.

This rule is your best defense against overselling. When a flash sale or an unexpected surge in orders occurs, the system holds back that 20-unit buffer, preventing you from selling reserved stock. This is critical for protecting your seller ratings on platforms like Shopee and Lazada, where stockouts can lead to penalties.

For multi-channel sellers, this is essential. A system like OneCart allows you to set these rules once and sync them instantly across Shopify, TikTok Shop, and all your marketplaces. If you’re just getting started with the numbers, our safety stock calculator can help you determine the right buffer for each product.

A common mistake is applying the same safety stock number to a product across all sales channels. A product might sell quickly on Lazada but be a slower seller on your Shopify store. A one-size-fits-all approach is inefficient and ties up cash unnecessarily.

A smarter strategy is to set safety stock on a per-channel basis. This allows you to tailor your buffer to match the unique sales patterns and risks of each marketplace.

Practical Example: Let’s say you sell a popular coffee blend. Your Shopee store often gets large orders during flash sales, while your own website sees more predictable purchases.

- On Shopee: You might set a higher safety stock of 50 units to absorb unpredictable spikes.

- On Shopify: A smaller safety stock of 10 units is likely sufficient.

This segmented approach provides a strong buffer where the risk is highest without hoarding unnecessary stock on lower-risk channels. It’s a more precise way to manage inventory that protects your revenue and frees up cash flow.

Automation is not just about setting limits; it’s also about triggering action. The final piece is setting up low-stock alerts that notify you when your inventory dips to its safety level.

These alerts are your cue to reorder. When your available stock is sold down to the buffer, your system should send an email or dashboard notification. This alert signals that it’s time to place a new purchase order with your supplier.

This step transforms your inventory management from a reactive process to a proactive one. You’re no longer waiting for a stockout to realize you need more inventory. Instead, you get a timely heads-up that lets you restock before you run out, keeping your supply chain smooth and your customers happy.

Even with the best formulas, questions can arise during implementation. Here are answers to common challenges sellers face.

Safety stock should not be a “set it and forget it” number. For most products, a monthly or quarterly review is a good practice. This is frequent enough to adapt to market changes without being overly burdensome.

However, some situations require more frequent reviews:

Actionable Insight: Set a recurring calendar reminder for the first Monday of each month to review the safety stock for your top 20% of products. This simple habit ensures your most important inventory is always protected by fresh data.

Choosing a service level doesn’t have to be a permanent decision. For most ecommerce businesses, a 95% service level is a strong, balanced starting point.

This target provides high product availability, keeping customers happy and sales flowing, without tying up excessive cash in inventory. It’s a sweet spot between satisfying demand and maintaining healthy cash flow.

Once you are comfortable with this baseline, you can make strategic adjustments. You might increase the service level for your best-sellers to 99% because a stockout would be highly detrimental. For slow-moving items, you might lower the level to 85% to free up capital.

Yes, but only in specific situations. A zero safety stock strategy is suitable for business models designed to avoid traditional inventory risk.

You could consider a zero safety stock approach if your products are:

For the majority of businesses selling physical goods, holding at least some safety stock is essential to prevent costly stockouts.

Ready to stop overselling and turn your safety stock calculations into an automated shield for your business? With OneCart, you can sync your inventory rules across Shopee, Lazada, and Shopify in seconds, set per-channel buffers, and get low-stock alerts that keep you ahead of demand. Start managing your inventory smarter today.

Automate & Scale Your Online Business with OneCart

Start a Free TrialUsed by hundreds of merchants in Singapore & Southeast Asia