The Perpetual Stock System Your Guide to Ecommerce Accuracy [2026]

Discover how a perpetual stock system can eliminate overselling and boost profitability. Get actionable strategies for seamless inventory management.

Discover how a perpetual stock system can eliminate overselling and boost profitability. Get actionable strategies for seamless inventory management.

A perpetual stock system is an inventory management method that gives you a real-time, continuous count of every single item you own. Every sale, return, or new shipment instantly updates your total stock levels, so you always have a live, accurate view of your inventory.

Imagine trying to follow a basketball game by only checking the scoreboard at the end of each quarter. You’d get the final outcome, but you would miss all the crucial plays that changed the game’s momentum. A traditional periodic inventory system works similarly—it gives you a snapshot in time, often weekly or monthly.

Now, picture a live scoreboard that updates with every single point. That’s a perpetual stock system for your inventory. It’s a dynamic approach where your stock records are continuously and automatically updated with every transaction.

For example, the moment a customer buys a t-shirt on your Shopify store, your inventory count for that specific SKU instantly drops by one. When a new shipment of 50 t-shirts arrives at your warehouse and gets scanned in, your count immediately increases by 50.

For multichannel sellers juggling platforms like Lazada, Shopee, and TikTok Shop, this real-time visibility is essential. Without it, you operate with outdated information, which leads to critical errors like selling products you no longer have. A perpetual stock system ensures the inventory numbers your customers see are always the right ones, building trust and preventing frustration.

A perpetual stock system acts as your single source of truth for inventory. It removes guesswork and manual checks, empowering you to make confident decisions based on what you have right now, not what you had yesterday.

This constant flow of data creates a solid foundation for your entire operation. It fundamentally shifts inventory management from a reactive, periodic chore to a proactive, ongoing process.

The difference in accuracy between inventory methods is significant. Industry analyses show businesses using perpetual inventory can hit up to 95% accuracy in their stock levels. Compare that to just 60-70% for those still relying on periodic methods.

This precision directly slashes overselling incidents by as much as 40% during peak sales events like 11.11, when every second counts. You can read more about the findings on inventory accuracy to see the full impact.

A perpetual stock system provides the clarity you need to handle a growing order volume and protect your seller reputation across every channel you sell on.

A modern perpetual stock system is a coordinated team of technologies working in sync to maintain a live, accurate inventory count. It’s an ecosystem of tools designed to capture, process, and share data the moment an item moves.

Let’s break down the core components that make this real-time tracking happen. Each part plays a specific role, turning individual scans and sales into a unified, accurate view of your entire stock.

It all starts with capturing data at every point an item moves. Tools like barcode scanners and RFID readers act as the system’s eyes and ears, removing the need for slow, error-prone manual entry.

This instant data capture is the foundation. Every scan is a precise, time-stamped event that feeds directly into the central system, eliminating the lag time and human error that plague manual tracking.

All that data flows into a central software platform that acts as the system’s brain. This is usually a Warehouse Management System (WMS) for businesses with significant warehouse operations or a Point of Sale (POS) system for retail stores.

The WMS or POS is the single source of truth. It processes every transaction, knowing when stock is added, sold, returned, or moved between locations. It’s the core database holding the master count for every single SKU you carry.

Think of your WMS as an air traffic controller for your inventory. It tracks every inbound shipment (landing) and every outbound order (takeoff), ensuring no two items are ever assigned to the same physical or digital space.

This central brain doesn’t just store numbers; it runs the logic. It knows which orders to prioritise, where to find specific items in the warehouse, and when to flag low-stock items for a reorder.

Once the central brain updates the master stock count, that new number needs to be shared instantly across all your sales channels. Real-time synchronization technology acts as a critical, high-speed messenger.

For any multichannel seller, this is a powerful feature. When an item sells on Shopee, the sync technology immediately tells your Shopify store, your Amazon shop, and your TikTok Shop that there is one less unit available. This entire process happens in seconds, preventing the dreaded oversell—where multiple customers buy the last item at the same time.

This constant, rapid communication ensures that every customer, on every platform, sees the exact same, up-to-the-minute stock availability.

Even with all this automation, a perpetual stock system needs a way to stay grounded in reality. Items get damaged, misplaced, or even stolen. That’s where cycle counting comes in.

Instead of a massive, disruptive annual stocktake that shuts down operations, cycle counting involves small, regular physical checks of your inventory. For example, your team might count a specific shelf or a small group of high-selling SKUs each day.

This ongoing audit process catches small discrepancies before they become big problems. If the physical count for a SKU is 98 but the system shows 100, you can investigate and correct the record right away. This simple practice keeps the entire system honest and ensures your data stays reliable.

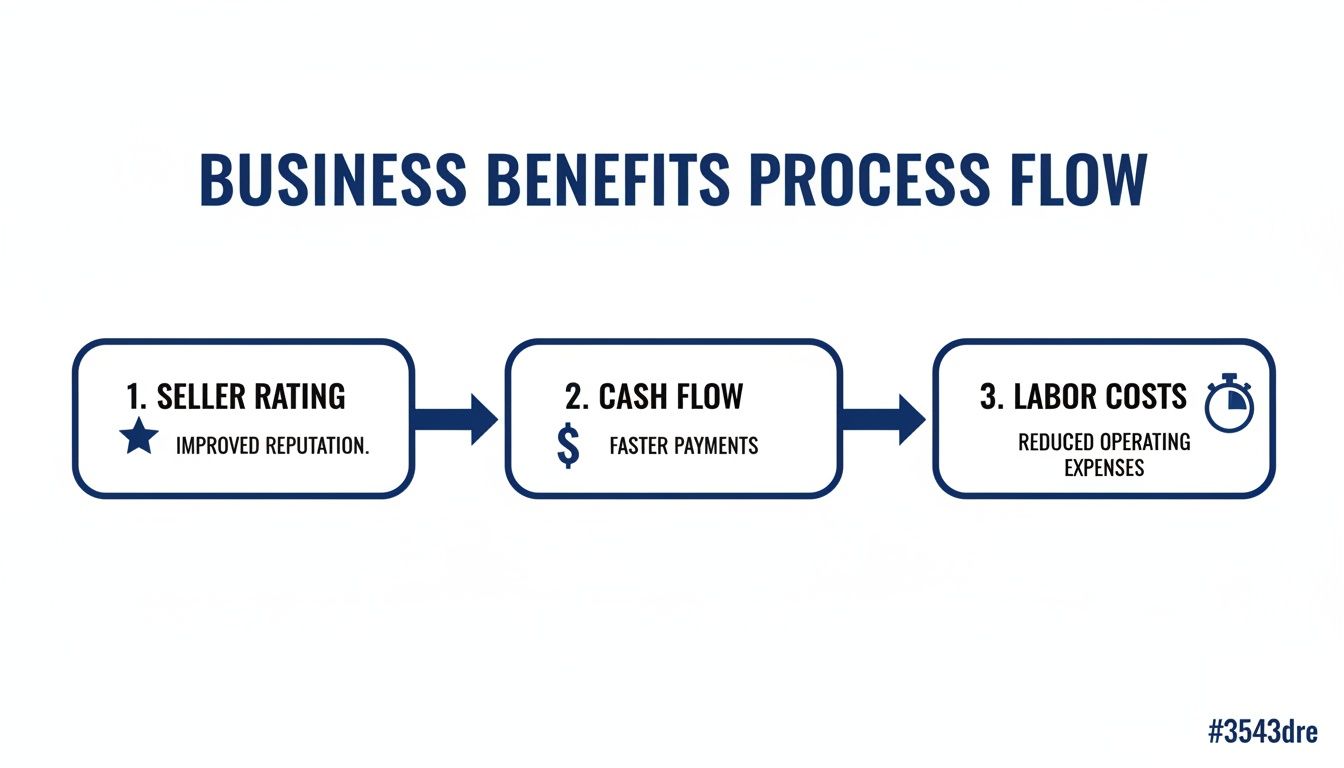

Moving to a perpetual stock system unlocks real, measurable advantages that directly strengthen your business. The live data you get fuels smarter decisions that protect your reputation, free up your cash, and make your entire operation run smoother.

Let’s get into the practical results you can expect.

On competitive marketplaces like Lazada or Shopee, your seller rating is your lifeline. A great rating builds trust and improves your visibility. A bad one can get your listings buried or, even worse, get you suspended.

The fastest way to damage that rating is by cancelling an order because you sold something you didn’t actually have in stock.

A perpetual stock system is your best defence against this. By giving you a single, accurate source of inventory truth that syncs everywhere you sell, it helps eliminate overselling.

For example, when a customer on your Shopify site buys that last blue widget, the system instantly tells your Lazada and TikTok Shop listings to show “Out of Stock.” This stops another customer from buying a ghost product, saving you from order cancellations and the angry reviews that follow.

Actionable Insight: By preventing oversells, a perpetual system directly safeguards your marketplace performance metrics. It ensures you meet customer expectations for order fulfillment, which is a core component of maintaining a high seller rating and staying in the platform’s good graces.

Cash is the lifeblood of any e-commerce business, and nothing drains it faster than money tied up in inventory that just sits there. A perpetual system gives you the clear, real-time data you need to spot these slow-moving products, often called dead stock.

Instead of waiting for an annual stocktake or relying on a gut feeling, you can see exactly which SKUs haven’t moved in months. This lets you take action right away.

This data-driven approach keeps your capital moving and working for you. For any brand serious about its finances, getting inventory under control is the first step. If you want to dive deeper, you might be interested in exploring our detailed guide on choosing the right inventory management system in Singapore.

An analysis from Inbound Logistics found that businesses using perpetual systems can slash dead stock losses by 35%. The same report showed inventory turnover rates climbing by 30% as brands optimized their reorders and cut down on obsolete products. You can discover more insights about how AI is preventing losing retail trades on newswire.com.

Traditional, all-hands-on-deck manual stocktakes are a massive disruption. They often mean shutting down your warehouse for a day or more, pulling your team away from sales and customer service, and they’re still filled with human error.

A perpetual stock system, combined with regular cycle counting, makes those events a thing of the past. Instead of a once-a-year fire drill, checking inventory becomes a small, routine task that’s part of your daily workflow.

This shift does two things: it slashes the direct labor costs of manual counts and gets rid of the opportunity cost of pausing your business. Your team can stay focused on what actually makes money—like packing orders and helping customers—instead of spending hours counting boxes. The system handles the tedious work, freeing up your people to focus on growth.

Understanding a perpetual stock system in theory is one thing, but seeing it work in a real-world setting makes its value clear. The system becomes the central hub for your entire multichannel operation, pulling all your sales channels into one smooth, unified workflow.

Let’s walk through how a central management tool puts your perpetual system to work, from syncing products to handling sales and returns across multiple platforms.

The first step is building a unified product catalog. Instead of juggling separate product listings on Shopify, Shopee, and TikTok Shop, you sync them all to a single, central dashboard.

Practical Example: You just received a new t-shirt design. You create the product in your Shopify store first, adding the SKU, description, images, and price. A central platform like OneCart then pulls this information and lets you push that exact same listing to Shopee and TikTok Shop, creating a linked, single source of truth for your inventory.

This simple action ensures that SKU “TSHIRT-SUMMER-BLUE-M” is the same item across all three channels. From now on, any sale or stock movement for this SKU will be tracked from one place, breaking down the data silos that cause so many inventory headaches.

Getting this right isn’t just about efficiency; it has a direct impact on your bottom line.

As you can see, accurate stock management directly improves your seller rating, frees up cash by cutting down on dead stock, and lowers your labor costs by taking manual tasks off your plate.

Now, let’s follow a live order to see the system in action. You have 10 units of that summer t-shirt in stock, and that number is synced everywhere.

A customer on Lazada orders one shirt. Here’s what happens next in your perpetual system:

This immediate sync is what stops overselling in its tracks. Without it, another customer could have easily bought that same “last” t-shirt on a different platform just moments later, forcing you to cancel an order and damage your seller reputation.

The process works just as smoothly in reverse. Let’s say a customer who bought the t-shirt from your Shopee store decides to return it. Once you get the item back at your warehouse and confirm it’s in sellable condition, you process the return in your central dashboard.

The system immediately adds one unit back into your available inventory. The master count for the SKU goes from 9 to 10, and that updated number is instantly reflected on Lazada, Shopify, and TikTok Shop. You can learn more about how to choose the right inventory software in Singapore to handle these kinds of complex workflows.

A critical feature of any solid perpetual stock system is a detailed audit trail. Think of it as a logbook that records every single stock movement—every sale, return, new shipment received, and manual adjustment.

If you ever find yourself wondering about a stock count that doesn’t add up, the audit trail has the answer. It shows you exactly who did what and when, creating complete accountability.

For example, you can see that a Shopee order reduced stock, a Lazada return increased it, and a team member manually adjusted a count after a spot check. This level of transparency is essential for troubleshooting discrepancies and trusting your data.

Finally, the system uses all this live data to generate powerful reports. You can monitor key metrics like sell-through rate and stock turnover, helping you make smarter purchasing decisions and keep your inventory lean and profitable.

Switching to a perpetual stock system is a significant upgrade, but it comes with potential hurdles. Knowing what these are ahead of time and having a plan is the secret to a smooth rollout.

Most challenges fall into three categories: bad data, tech hiccups, and team adoption. Let’s walk through each one and discuss practical ways to keep your project on track.

The single biggest reason new perpetual systems fail is that they start with bad data. If your initial stock counts are off, your system will be inaccurate from day one, leading to phantom stock, overselling, and reports you can’t trust.

This usually happens because the initial stocktake was rushed or sloppy. A few small miscounts here, a pallet of items in the wrong aisle there, or a stack of unprocessed returns can corrupt your entire baseline. These small errors create problems that will haunt your operations for months.

The accuracy of your entire perpetual system hinges on the quality of your Day One data. A meticulous, wall-to-wall physical count before you import anything is not just a best practice; it’s a non-negotiable prerequisite for success.

Actionable Insight: Before you import a single number, perform a complete, disciplined physical inventory count. If possible, freeze all stock movements for 24-48 hours to ensure the count is perfect. Once you’re live, set up a strict cycle counting schedule to maintain that accuracy, starting with your fastest-moving products.

A perpetual stock system is a team of connected hardware and software working together. When one part stops talking to another, the whole thing can grind to a halt. You might encounter barcode scanners that won’t connect to the Wi-Fi in the back corner of the warehouse or software integrations that fail to sync.

For example, your WMS might not get sales data from your new TikTok Shop integration. Stock levels won’t update even as orders fly in. This creates a dangerous blind spot and defeats the purpose of having real-time data.

Actionable Insight: Minimize these conflicts by choosing a unified platform that acts as a central hub, which reduces the number of direct connections you have to manage. Test all your hardware—scanners, printers, and other devices—in every corner of your facility before the full rollout. Run extensive end-to-end tests for every single sales channel to confirm data flows correctly both ways, from sales out to returns back in. For businesses navigating these complexities, considering the benefits of outsourcing accounting services can be a valuable strategy to overcome common challenges.

Never underestimate the human element. Your team is likely used to the old, manual way of doing things. Bringing in new tech and changing workflows can be met with confusion or resistance if not handled correctly. If your staff isn’t trained on the new scanners or doesn’t understand the point of cycle counting, they’ll fall back on old habits and slowly undermine the entire system.

Actionable Insight: Invest real time in training that explains the “why” behind the new system, not just the “how.” Show your team how it makes their jobs easier by getting rid of manual counts and cutting down on frustrating errors. Create simple, clear documentation and designate a “super-user” on the floor who can answer questions and offer immediate help.

Making the leap from a periodic system to a perpetual one is a massive operational upgrade. To pull it off without creating chaos, you need a clear, strategic plan. A rushed implementation can cause more headaches than it solves, so follow this roadmap to guide your migration and set your business up for success.

This isn’t just about plugging in new software. It’s about building a solid foundation of accurate data, the right tech, and a team that knows how to use it.

Before you can trust a single number in your new system, you need an undisputed starting point. The single most critical step in this entire process is conducting one last, exhaustive physical inventory count. This isn’t just another stocktake; it’s the bedrock of your entire perpetual system.

Think of it like calibrating a sensitive instrument. If your initial measurement is off, every single reading that follows will be flawed. A perfect baseline count ensures your system reflects reality from day one.

Schedule a time to freeze all stock movements—no receiving, no shipping, nothing in or out. Your team needs to count every single item in every bin, on every shelf, in every corner. This meticulous effort is the best investment you can make in future accuracy. It single-handedly eliminates the “garbage in, garbage out” problem that dooms so many migrations.

With a clean, accurate baseline established, it’s time to focus on the tech stack. This is the engine that will run your new perpetual system, and the choices you make here will directly impact your team’s efficiency and your ability to scale.

Technology is only as good as the people using it. A well-trained team is absolutely essential for maintaining the integrity of your new system day in and day out. Give them hands-on training that covers the new daily workflows, from scanning new arrivals and picking orders to performing regular cycle counts.

To minimize disruption to your daily operations, avoid a “big bang” launch where everything goes live at once. A much safer approach is a phased rollout:

Finally, you need to know if all this effort was actually worth it. Define clear Key Performance Indicators (KPIs) to track your return on investment. This data will prove the value of your new perpetual stock system and help you pinpoint areas for further improvement.

Key metrics to keep a close eye on include:

After digging into the nuts and bolts of a perpetual stock system, you might still have a few questions floating around. That’s perfectly normal. This section tackles the most common queries we hear from brands getting ready to make the switch.

While you can finally say goodbye to chaotic, all-hands-on-deck annual stocktakes, you absolutely still need to do physical counts. The difference is how you do them. The best practice is cycle counting—counting small, manageable sections of your inventory on a rotating basis.

This approach turns a massive annual headache into a simple, continuous process. You’ll catch small issues like theft, damage, or human error before they snowball into major discrepancies, keeping your data clean without ever having to shut down operations.

Actionable Insight: You could count your top 20 fastest-selling SKUs every week, your mid-tier products monthly, and your slow-movers once a quarter. This focuses your energy where it matters most.

Absolutely. In fact, it’s often the perfect time to set one up. The moment you start juggling dozens of orders a day, especially across more than one sales channel, trying to track stock manually becomes a massive liability.

A perpetual system automates all of that, saving you countless hours and preventing the kind of overselling mistakes that can damage your reputation. It builds a foundation that lets you scale from 50 orders a day to 500 without the operational chaos that holds many great brands back. You’re preparing for growth instead of just reacting to it.

Actionable Insight: Implementing a perpetual system early is an investment in your future sanity. It lets you focus on marketing and sales, knowing your backend operations can actually handle the success you’re aiming for.

The single biggest mistake is starting with bad data. If you import flawed stock numbers into your new perpetual system, you’ll be chasing phantom inventory problems from day one.

Actionable Insight: Before you go live, you must perform a complete, meticulous physical count of every single item you own. This clean slate ensures your system’s data reflects reality, giving you a reliable foundation for all future tracking. Don’t cut corners here—it’s the most important step you’ll take.

Yes, and this is one of its most powerful features for your finances. A core function of any good perpetual stock system is tracking your Cost of Goods Sold (COGS) in real time.

Every time an item is sold, the system instantly logs the associated cost from your inventory records. This gives you an up-to-the-minute view of your gross profit and overall financial health. This is a huge step up from periodic systems, where COGS is only calculated at the end of the month, leaving you to guess your profitability in the meantime.

Ready to eliminate overselling and unify your multichannel operations with a powerful perpetual stock system? See how OneCart centralizes your inventory, orders, and listings from Shopee, Lazada, TikTok Shop, and Shopify into a single, real-time dashboard. Schedule a demo today!

Automate & Scale Your Online Business with OneCart

Start a Free TrialUsed by hundreds of merchants in Singapore & Southeast Asia