Explore the last mile delivery service: Boost efficiency & loyalty 2026

Discover the last mile delivery service and how to cut costs, improve KPIs, and boost customer loyalty with practical insights.

Discover the last mile delivery service and how to cut costs, improve KPIs, and boost customer loyalty with practical insights.

A last mile delivery service handles the final, most crucial step in a product’s journey: getting a package from a local hub to a customer’s front door. This is almost always the most expensive and complicated part of shipping, but it’s also the one that defines the customer’s experience.

Getting this final step right is what separates a good buying experience from a great one.

Think of your product’s journey like a relay race. The first few legs—moving inventory in bulk from a factory to a warehouse—are efficient and predictable. But the last mile is the final, high-stakes leg where the baton is passed directly to your customer.

Unlike the earlier stages of shipping full pallets, this final step is a one-to-one transaction. It’s personal, highly visible, and has a huge impact on how a customer feels about your brand. A single delay or a crushed box can instantly undo all the hard work you put into your marketing and sales.

The last mile is your single best chance to build trust and earn repeat business.

Imagine you run a small online store selling handmade candles. You spend weeks perfecting your product, building a beautiful website, and running ads. A customer finally places an order, excited to get their candle. Now, the last mile delivery service takes over.

Actionable Insight: Treat your delivery experience as a direct extension of your brand. Your chosen courier is the only physical interaction most e-commerce customers will ever have with your business.

This final step is only getting more important as customer expectations soar. The demand for fast, reliable, and transparent shipping is fueling massive growth in the sector.

The last-mile delivery market is projected to more than double from USD 133.5 billion in 2025 to USD 266.1 billion by 2033. This final leg of the journey eats up 53% of total logistics costs, making it absolutely essential to get it right for your profitability.

Mastering this final stage is a key differentiator in a crowded market. It’s where you deliver on the promise you made when the customer clicked “buy.” Whether you handle logistics yourself or use a partner, understanding the third-party logistics industry is a great next step.

The final leg of delivery is where you win or lose your customer’s loyalty. This crucial last step is also riddled with operational landmines that can obliterate profits and tarnish your brand’s reputation.

To run a successful last-mile operation, you have to face these issues head-on. Let’s break down the three biggest hurdles every e-commerce business runs into.

The biggest challenge in last-mile delivery is the staggering cost. This single step can easily eat up a huge slice of your entire logistics budget, often in ways that are tough to see until you’re already in the red. The expenses sneak up on you from all directions.

The main cost drivers are:

Practical Example: A small business owner might see their courier fees double during the holiday rush. This is the direct result of higher fuel prices, driver overtime, and the immense strain on the whole delivery network. Every sale becomes a little less profitable.

Modern customers expect their orders practically yesterday. Same-day or next-day delivery has gone from a premium perk to a standard expectation, putting incredible pressure on businesses to make their fulfillment process faster than ever.

Meeting this demand is a logistical challenge. It means you need inventory stored close to your customers, lightning-fast picking and packing in your warehouse, and a network of couriers ready to roll at a moment’s notice. A single hiccup in this chain leads to a missed delivery window and an unhappy customer. This pressure often forces businesses into paying premium rates for express shipping, pushing costs even higher.

The reality is that last-mile delivery often consumes over 50% of total supply chain expenses. However, the market continues to expand, with projections showing growth from USD 200.95 billion in 2025 to USD 315.69 billion by 2029, largely driven by e-commerce. You can find more details in this last mile delivery market report.

A failed delivery attempt is one of the most frustrating—and expensive—events in the last mile. This happens when a driver shows up, but the customer isn’t home to sign for the package, or worse, the address is wrong.

Each failure triggers a domino effect. The package has to be hauled back to the depot, stored, and then rescheduled for another trip, effectively doubling the labor, fuel, and admin costs for that one order. Beyond the financial hit, it creates a terrible customer experience that clogs up your support channels with complaints.

This brings us to one of the most common last-mile hurdles: handling your delivery and returns policy effectively. A clear and painless returns process can turn a bad experience into a chance to win a customer for life. It’s a non-negotiable part of any solid last-mile strategy.

To tie this all together, here’s a quick look at how these common challenges directly impact your business.

| Challenge | Primary Drivers | Impact on Business |

|---|---|---|

| High Costs | Fuel prices, driver wages, vehicle upkeep, inefficient routing, premium shipping fees. | Erodes profit margins on every sale, makes competitive pricing difficult, and can lead to unsustainable cash flow. |

| Speed Expectations | Customer demand for same-day/next-day delivery, competitive pressure from retail giants. | Increases operational complexity, drives up labor and shipping costs, and risks brand damage from missed deadlines. |

| Failed Deliveries & Returns | Incorrect addresses, customer unavailability, difficult access points, complex returns processes. | Doubles delivery costs for a single order, creates negative customer experiences, increases support workload, and adds reverse logistics expenses. |

As you can see, these aren’t just minor operational headaches. Each one has a direct and measurable impact on your bottom line and your brand’s reputation, making a well-thought-out last-mile strategy essential for survival.

If you can’t measure your delivery operations, you can’t improve them. To get a grip on your last-mile delivery service, you have to move beyond guesswork and start tracking specific, actionable numbers.

These key performance indicators (KPIs) are like a health check for your entire fulfillment process. They show you exactly where you’re winning and, more importantly, where you need to focus your attention.

Tracking the right data helps you make smarter, more profitable decisions. You can spot costly problems before they get out of hand and find new ways to give your customers a better experience. Let’s dig into the essential metrics that successful businesses live by.

This is the most direct measure of your promise to the customer. The On-Time Delivery Rate (OTDR) simply calculates the percentage of orders that show up within the promised timeframe. A high OTDR is a powerful sign of a reliable and efficient delivery network.

Speed is great, but it has to be balanced with profitability. Cost Per Delivery (CPD) measures the average expense to get a single package to its final destination. This number includes everything—fuel, vehicle maintenance, driver wages, and software fees.

This KPI is critical because last-mile delivery can eat up over half of your total shipping expenses. Keeping a close eye on your CPD ensures your shipping strategy remains financially sustainable.

Actionable Insight: You might notice your CPD spikes during peak season. By tracking this, you can decide whether to add a temporary delivery surcharge or use slower, more economical shipping options for non-urgent orders to protect your profit margins. Knowing your numbers empowers you to make these kinds of strategic adjustments.

To dive deeper into this topic, learn more about the top ecommerce metrics and KPIs to track for business success.

A failed delivery is more than just an inconvenience. It doubles your costs for that order and creates a genuinely frustrating experience for your customer. The First Attempt Delivery Success Rate (FADR) tracks the percentage of orders successfully delivered on the very first try.

Knowing your numbers is the first step. Now it’s time to act. Fixing your last-mile delivery is about giving drivers smarter tools and better strategies. By focusing on proven methods, you can directly attack high costs, speed up deliveries, and give your customers a much better experience.

Let’s walk through five practical strategies that can make a real difference in your day-to-day operations, turning logistical headaches into a genuine competitive advantage. Each one offers a unique way to tighten up your process, cut waste, and build a more resilient delivery system.

One of the fastest ways to burn through your budget is with clumsy delivery routes. Every time a driver gets stuck in traffic, backtracks across town, or takes a longer route, you’re wasting fuel, paying for extra hours, and delaying packages. Route optimization software tackles this problem head-on.

This technology uses smart algorithms to weigh multiple factors in real time—think traffic jams, specific delivery windows, how much a van can hold, and even the weather. Instead of a driver guessing the best order of stops, the software creates the most efficient route in seconds.

Actionable Insight: Adopting solid last-mile delivery best practices is fundamental to getting this right, and these tools are the foundation for a leaner, more cost-effective operation.

Think of crowdshipping as an on-demand delivery service. This model taps into a network of independent local couriers who use their own cars, bikes, or vans to make deliveries. For any business with unpredictable order volumes, this offers incredible flexibility without the massive overhead of owning and maintaining a big in-house fleet.

Practical Example: A local bakery gets a huge spike in orders for a holiday weekend. Instead of scrambling to buy a new van or overworking their one driver, they can plug into a crowdshipping platform to handle the overflow. This lets them scale up instantly and then scale right back down when things quiet down, only paying for the deliveries they actually need.

Actionable Insight: Crowdshipping is a brilliant move for managing peak seasons, testing out same-day delivery in a new city, or just handling the extra load when your main fleet is maxed out. It flips a fixed cost (vehicle ownership) into a variable one (per-delivery fee).

A failed delivery is a massive drain on your resources. One of the simplest ways to nearly wipe them out is to give customers more convenient pickup options. Delivery lockers and Pick-Up/Drop-Off (PUDO) points are secure, easy-to-access spots where people can grab their packages whenever it suits them.

These options are a win-win for everyone involved:

Today’s customers want to know exactly where their package is at all times. Offering real-time, transparent tracking is a basic expectation. This visibility drastically cuts down on customer anxiety, which in turn slashes the number of “Where is my order?” calls to your support team.

Actionable Insight: A customer who can see their package moving on a map is far less likely to tie up your phone lines. This frees up your staff to handle more complex problems while giving the customer a sense of control and confidence in your brand.

A difficult returns process can quickly sour a customer relationship. Making returns easy and hassle-free is a critical part of last-mile optimization. A solid reverse logistics system needs to be both friendly for the customer and efficient for your business.

Actionable Insight: Offer a few different options, like including a pre-printed label in the box, allowing QR code-based returns at courier locations, or letting customers drop packages at the same PUDO points they use for pickups.

To help you decide which approach fits best, here’s a quick comparison of the strategies we’ve discussed. Each has its own strengths, depending on your business model and biggest pain points.

| Strategy | Key Benefit | Best For | Implementation Note |

|---|---|---|---|

| Route Optimization | Reduced Fuel & Labor Costs | Businesses with in-house fleets making multiple stops per run. | Requires software integration and initial driver training. |

| Crowdshipping | Scalability & Flexibility | Companies with fluctuating demand or those expanding into new urban areas. | Vetting crowdshipping partners for reliability is key. |

| Lockers & PUDO Points | Eliminates Failed Deliveries | E-commerce brands with high delivery density in urban and suburban areas. | Depends on building a network of accessible partner locations. |

| Real-Time Tracking | Improved Customer Experience | All direct-to-consumer businesses. | Integrates with your TMS and requires a customer-facing interface. |

| Streamlined Returns | Increased Customer Loyalty | Retailers, especially in fashion and electronics where returns are common. | Needs clear policies and coordination between logistics and customer service. |

Mixing these technology-driven strategies is the key to modernizing your operations. Sustainability and new tech are huge drivers here; using route optimization AI can slash fuel costs by 10-15%. New ideas like urban logistics hubs and autonomous vehicles could even lead to cost reductions of up to 20%, according to recent market analysis.

Picking a delivery partner is a deeply strategic decision. You’re choosing an extension of your brand. For most online businesses, this partner is the only physical touchpoint a customer has with you.

Their performance is a direct reflection of your own. A bad choice leads to lost packages, angry customers, and a reputation that’s tough to repair. Get it right, and you build loyalty that drives repeat business. This isn’t a decision to be rushed. It requires a hard look at how a partner’s skills line up with your brand promise and day-to-day needs.

While cost always matters, it should never be the only factor. A cheap courier with a reputation for late deliveries or radio silence will cost you far more in customer support tickets and lost sales than you save on shipping fees.

To make a smart choice, you need to dig into three critical areas that reveal a partner’s true value.

Service Level Agreements (SLAs): An SLA is a formal contract defining the service you can expect. It should spell out commitments for on-time delivery rates, how lost or damaged packages are handled, and what happens when delays occur. Vague SLAs are a massive red flag.

Geographic Reach and Density: Can they actually deliver where your customers are? A courier might offer great rates for city centers but fall apart on suburban or rural routes, leading to delays and surprise surcharges. Ask for a detailed breakdown of their coverage map and performance data in your key delivery zones.

Technology Integration: Seamless tech is non-negotiable. A good partner must offer a robust API that plugs right into your order management system. This is what enables automated label printing, gives customers real-time tracking, and makes the whole data exchange feel effortless.

Actionable Insight: Ask potential partners for case studies or references from businesses similar to yours. A five-minute chat with a current client will give you a much clearer picture of a courier’s real-world performance than any sales pitch ever could.

When you’re ready to sit down with potential partners, use this checklist to guide the conversation. Their answers will tell you a lot about their operational maturity and how they react when things inevitably go sideways.

Essential Questions to Ask:

This level of scrutiny is essential. For many businesses, outsourcing this entire headache to a third-party logistics provider is a strategic move. If you’re exploring this path, you can learn more about 3PLs in Singapore to see how they can manage these partnerships for you.

Let’s make this real. Imagine you’re running an online store and you’re down to two courier options.

Courier A (The Budget Option): Their rate is 15% cheaper per parcel, which looks great on paper. But they have no API, forcing your team to manually upload order details in a spreadsheet every single day. Their tracking is basic, only updating when a package is “out for delivery” and “delivered.”

Courier B (The Tech-Forward Partner): Their rate is a bit higher, but they offer full API integration. This means labels are generated automatically as orders come in, tracking numbers sync instantly, and customers get live updates from start to finish. They also guarantee a 98% on-time delivery rate in their SLA.

Choosing Courier A might save you a few bucks upfront, but the manual workload will quickly become a major time sink, increasing the odds of human error. The vague tracking will also flood your inbox with “Where’s my order?” emails.

Courier B, while costing more per shipment, offers efficiency and a superior customer experience that protects your brand and frees up your team. The right choice is the one that delivers long-term value, not just short-term savings.

Alright, we’ve covered the strategies and the importance of finding the right delivery partners. Now it’s time to put that theory into action. This is your playbook for turning a messy, manual last-mile process into a smooth, automated operation.

If you’re selling across multiple marketplaces like Shopee, Lazada, and TikTok Shop, you know the pain of juggling dozens of browser tabs, spreadsheets, and courier portals. It’s a recipe for mistakes and wasted hours. The goal here is to pull everything into one command center, giving you back your day and seriously upgrading your delivery game.

The first, most powerful move is to funnel all your incoming orders into a single dashboard. Stop logging into each marketplace one by one just to see what you’ve sold. A platform like OneCart syncs every order automatically, in real-time.

This simple change completely gets rid of the soul-crushing, error-prone task of copying and pasting order details. Instantly, you have a single source of truth for your entire operation. You can see exactly what needs to be picked, packed, and shipped across all your channels at a single glance.

Practical Example: Imagine you sell on three different marketplaces. The old way involves downloading three separate order lists, trying to merge them in a spreadsheet, and manually checking for duplicates or special customer requests. With a central platform, all those orders just show up in one neat queue, already sorted and ready to go.

Once your orders are all in one place, the real magic begins. The next step is to automate all those repetitive tasks that eat up your time and open the door to human error. This is where you’ll see massive gains in your fulfillment speed and accuracy.

Focus on automating these key jobs:

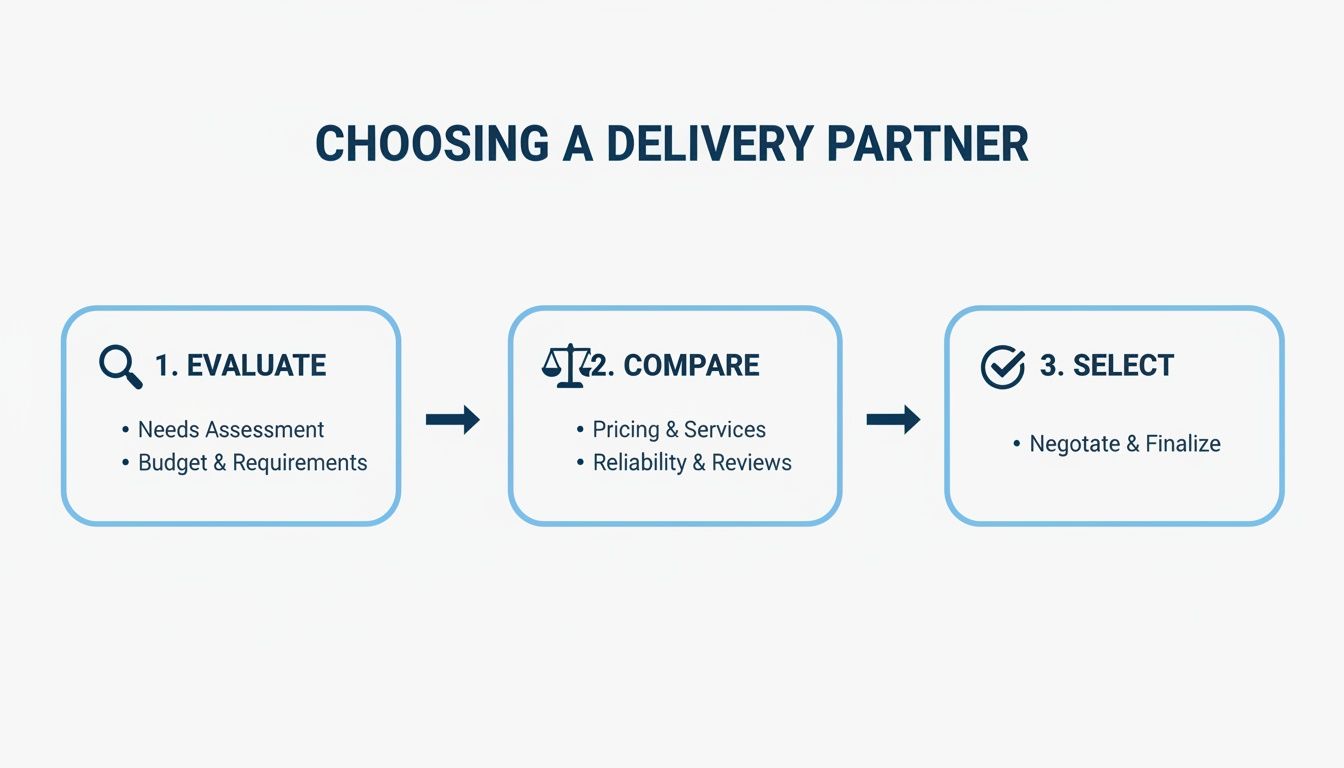

The graphic below shows the simple, three-step logic for choosing the right partners to plug into this kind of efficient workflow.

This visual breaks down the core decision-making process—evaluate, compare, and select—which gets a whole lot easier when all your operational data is in one spot.

The final piece of the puzzle is closing the loop to prevent problems down the road. A great system doesn’t just manage outgoing orders; it also keeps your inventory levels accurate across every single channel you sell on.

When an item sells on one marketplace, the platform instantly updates the stock count on all the others. This powerful, real-time sync is your best defense against overselling—a common mistake that leads to canceled orders and damaged marketplace ratings.

Finally, you can schedule courier pickups right from your dashboard. Once your packages are packed, labeled, and ready to roll, you just notify your delivery partner that the shipment is ready for collection. This one step saves time and ensures your orders get on their way without a hitch, which directly improves your on-time delivery metrics.

Every business owner has questions about last-mile delivery. It’s a complicated part of the business, and the details matter. Let’s clear up some of the most common queries we hear.

It almost always comes down to cost. The final leg of the journey is by far the least efficient piece of the entire supply chain. You’re dealing with individual stops, unpredictable city traffic, and ballooning fuel and labor expenses. This is exactly why the last mile can eat up over 50% of your total shipping costs.

Actionable Insight: Get a grip on your cost-per-delivery. This number tells you if certain routes, couriers, or even neighborhoods are draining your profits, letting you make smarter, data-driven changes to protect your margins.

Failed deliveries are a huge drain on your resources and a surefire way to frustrate customers. The best way to cut them down is to be proactive with communication and give your customers flexible options.

Actionable Insight: Send automated SMS or email alerts with a tight, two-hour delivery window and a live tracking link. Just doing this one thing dramatically increases the odds that your customer will be home to receive their package.

You should also look into services that let customers redirect a package to a local pickup point or a secure locker if they know they won’t be around. This approach practically guarantees a successful delivery on the very first try.

It’s a common point of confusion, but the distinction is pretty simple. A courier is the company that physically moves your packages from your warehouse to your customer’s doorstep. They’re the ones with the vans, bikes, and drivers making the actual deliveries.

A Third-Party Logistics (3PL) provider offers a much broader suite of services. They can handle your inventory storage, pick and pack your orders, and then manage relationships with multiple couriers to get the final delivery done. Think of a 3PL as your outsourced operations team that manages the whole fulfillment process, with last-mile delivery being just one piece of the puzzle they handle.

Ready to eliminate errors and automate your entire shipping process? OneCart brings all your orders from every marketplace into a single dashboard. You can bulk-print labels and schedule courier pickups in seconds. See how much time you can save.

Automate & Scale Your Online Business with OneCart

Start a Free TrialUsed by hundreds of merchants in Singapore & Southeast Asia