Mastering Last Mile Deliveries for Modern Ecommerce [2026]

A complete guide to mastering last mile deliveries. Learn key strategies, tech, and KPIs to reduce costs and boost customer loyalty on any ecommerce platform.

A complete guide to mastering last mile deliveries. Learn key strategies, tech, and KPIs to reduce costs and boost customer loyalty on any ecommerce platform.

Last-mile delivery is the final, critical step in the e-commerce journey: getting a package from a local warehouse or fulfillment hub to your customer’s doorstep. This is the moment of truth for your brand, the one physical interaction that shapes how a customer feels about their entire purchase.

A smooth, fast delivery can earn you a five-star review and a repeat customer. A single delay or a damaged box can lose you that customer for good.

Think of your supply chain as a relay race. The first few legs—manufacturing, bulk transport, warehousing—are essential but happen behind the scenes. The last mile is the final sprint. It’s where the baton (your product) is handed off for the most visible and scrutinized part of the race.

For an online brand, this is often the only physical touchpoint you have with your customers. It’s precisely at this stage where their expectations are sky-high. Today, buyers demand speed, transparency, and convenience, turning this final step into a fierce competitive battleground for sellers on Shopify, Shopee, and Lazada.

Last mile delivery is a core part of the customer experience. A great delivery experience builds trust and drives repeat business. A bad one can undo all the hard work you put into your marketing and product development.

Here’s why it’s become so critical:

The market trends tell the same story. The last-mile delivery market was valued globally at around USD 157.39 billion and is projected to explode to USD 403.34 billion by 2035. This massive growth mirrors the surge in online shopping, especially in fast-growing regions like Asia-Pacific, where e-commerce giants push merchants to fulfill thousands of orders every day. You can dig into more data on this incredible expansion from Spherical Insights and Consulting.

Shoppers today have been conditioned by retail giants to expect near-instant gratification. This puts enormous pressure on small and medium-sized businesses to keep up.

Modern standards now include real-time tracking, accurate delivery windows, and flexible options. A customer wants to know exactly when their package will arrive and be able to make changes if needed.

For instance, a customer ordering on Lazada might get a notification that their package is “out for delivery” and expect it within hours. If that window is missed without any communication, frustration builds fast.

Contrast that with a Shopify store that provides a live tracking link and sends an SMS alert 30 minutes before arrival. That creates a premium, trustworthy experience. Getting these details right is an essential key to winning in e-commerce.

While the final step of delivery seems straightforward, it’s often the most complex and expensive part of the entire fulfillment process. Several operational hurdles silently chip away at your profits, turning what should be a simple drop-off into a significant financial drain. These issues hit every business, from established brands on WooCommerce to new sellers on TikTok Shop.

Understanding these obstacles is the first step toward building a more resilient and profitable operation. Each problem creates a ripple effect, where a small logistical hiccup can lead to escalating costs and unhappy customers.

The single biggest headache in last-mile deliveries is the staggering cost—it now accounts for an incredible 53% of total shipping expenses, a huge jump from just 41% in 2018. Failed delivery attempts are a major culprit, costing businesses an average of nearly $18 per incident.

When a driver can’t complete a delivery, it’s not just a delay; it’s an expensive do-over. Globally, around 75% of customers have run into delivery problems, showing why efficiency is non-negotiable for modern merchants. You can find more insights on these challenges and their impact from SmartRoutes.

These costs aren’t abstract figures; they represent real money leaving your business. Each failed delivery triggers a sequence of costly actions, from additional fuel and labor for redelivery to the time your support team spends handling customer complaints.

Every day, delivery drivers face a minefield of issues that complicate their routes and inflate your expenses. These are recurring problems that compound over time, directly hitting your bottom line.

Here are some of the most common challenges:

Think about a single missed delivery in a dense urban area. The driver wastes time, the package goes back to the hub, a customer service ticket is created, and your team must reschedule—all of which costs money and erodes customer trust.

The table below breaks down these common challenges and their tangible business impact, showing just how quickly small issues can turn into major financial headaches.

| Challenge | Description | Direct Cost Impact | Customer Experience Impact |

|---|---|---|---|

| Failed Delivery Attempts | When a driver cannot complete a delivery due to an incorrect address, inaccessible location, or no one being available to receive the package. | Average cost of $18 per attempt, including extra fuel, labor, and administrative overhead for rescheduling. | High customer frustration, leading to negative reviews, increased churn, and damage to brand reputation. |

| Inefficient Routing | Drivers following unoptimized routes, leading to longer travel times, more fuel consumption, and fewer deliveries per shift. | Increased fuel expenses, higher driver overtime pay, and accelerated vehicle wear and tear. | Unpredictable and longer-than-expected delivery windows, which is a major pain point for modern consumers. |

| Urban Traffic Congestion | Time lost due to traffic jams, especially during peak hours in dense urban centers. | Lower driver productivity (fewer stops per hour), leading to a higher cost per delivery. | Delays that break the promise of fast shipping, eroding customer trust and satisfaction. |

| Poor Address Quality | Incomplete, incorrect, or unverified address data from order entry systems. | Wasted driver time searching for the correct location, increased fuel consumption, and higher rates of failed deliveries. | Orders delivered to the wrong address or returned to the warehouse, creating a frustrating and confusing experience for the customer. |

As you can see, these aren’t just minor annoyances. Each challenge directly translates into lost revenue and a poorer customer experience, making it critical to address them proactively.

For businesses selling across multiple platforms, these challenges are amplified. Managing orders from Lazada, TikTok Shop, and your own WooCommerce store means dealing with different data formats and customer expectations. A lack of a centralized system can lead to inconsistent address verification, fragmented communication, and a disjointed customer experience.

Each platform has its own set of rules and interfaces, making it tough to maintain a standardized, efficient workflow. Without a unified view, spotting and fixing these inefficiencies becomes nearly impossible. This is why proactive optimization is not just a goal but a necessity for survival and growth. Tackling these hidden costs head-on is essential for building a sustainable and profitable e-commerce business.

To improve your last-mile deliveries, you must start by measuring what matters. Without clear data, you are just guessing where the problems are. By tracking a few essential key performance indicators (KPIs), you can stop guessing and start making smart, data-backed decisions.

Think of these metrics as the health monitors for your entire logistics operation. They tell you exactly where you’re succeeding and, more importantly, where you’re losing money or letting customers down. This is especially true for multi-channel merchants juggling orders from places like Lazada and a Shopify store, where performance can vary depending on the courier or even the city.

The Cost Per Delivery is one of the most fundamental numbers you need to know. It’s the total expense of getting a single package from your warehouse to your customer’s doorstep. This includes everything—fuel, vehicle maintenance, routing software, and even the driver’s wage.

Knowing this number is critical because it directly impacts your profitability on every single order. A high Cost Per Delivery can silently eat away at your margins, particularly if you’re offering free or subsidized shipping to stay competitive.

The On-Time Delivery Rate (OTD) measures the percentage of orders that arrive within the promised timeframe. Customers today want their items delivered predictably fast. This KPI is a direct reflection of your reliability and the quality of your service. A high OTD rate builds trust and brings customers back.

Practical example: Imagine you sell on your own Shopify store and through Lazada. Your dashboard might show an overall OTD of 95%, which looks fantastic. But when you break it down, you might discover that your Shopify orders are hitting 98%, while deliveries in a key region serviced by one specific courier for Lazada are only at 85%. That single insight immediately points you to the weak link in your operation.

The Failed Delivery Rate tracks how many deliveries couldn’t be completed on the first try. Every single failed delivery is a costly headache. It triggers expenses for redelivery attempts, customer support time, and even potential inventory spoilage for perishable goods—not to mention it creates a terrible customer experience.

Common causes are simple but frustrating: incorrect addresses, customers not being home to receive the package, or inaccessible delivery locations like gated communities with no instructions. Keeping this rate as low as possible is essential for both your finances and your reputation.

Knowing your numbers is the first step. Turning those insights into action is what drives real improvement. Optimizing your last mile deliveries means making smart, proactive choices in three critical areas: how you fulfill orders, who you trust to deliver them, and how you handle returns.

Get these right, and you’ll see a direct impact on your costs and delivery times. More importantly, you’ll build the kind of customer loyalty that fuels long-term growth. It’s about creating a system that’s efficient for you and impressive for your customers.

Your fulfillment model is the engine of your entire delivery operation. It dictates where your products are stored, who picks and packs them, and how quickly they get on the road. There’s no single “best” model—the right choice depends on your order volume, product type, and business goals.

A new brand selling custom jewelry, for instance, might thrive with in-house fulfillment. It gives them total control over quality and the unboxing experience. But a rapidly growing clothing store processing hundreds of orders a day might find that outsourcing to a third-party logistics (3PL) provider is the only way to scale without getting buried in operational tasks.

For a comprehensive overhaul, some businesses turn to supply chain management outsourcing to bring in specialized expertise for the entire delivery pipeline, not just the last mile.

Another powerful option is a hybrid approach using micro-fulfillment centers (MFCs). These are small, localized warehouses placed in urban areas, much closer to your customers. By stocking popular items in an MFC, you can slash the final delivery distance, making same-day or next-day delivery not just possible, but affordable.

A clear comparison can help you decide which path makes the most sense for your business right now.

| Fulfillment Model | Best For | Pros | Cons |

|---|---|---|---|

| In-House Fulfillment | Startups, brands needing high-touch packaging, low-volume sellers. | Total control over quality, branding, and customer experience. No third-party fees. | Hard to scale quickly. Requires space, staff, and technology investment. Can be inefficient. |

| Third-Party Logistics (3PL) | Growing businesses, merchants wanting to focus on marketing and sales. | Expertise and efficiency. Access to better shipping rates. Easy to scale up or down. | Less control over branding and fulfillment. Can be costly for low-volume sellers. |

| Dropshipping | Sellers with a wide product range, businesses testing new products. | No inventory risk or upfront investment. Wide product selection possible. | Very low profit margins. No control over stock or shipping times. High competition. |

Ultimately, the best model is the one that aligns with your growth stage and customer promises. Don’t be afraid to switch or adopt a hybrid model as your business evolves.

Relying on a single shipping carrier is like having only one tool in your toolbox. It works for some jobs, but it’s rarely the best option for all of them. A multi-carrier strategy means partnering with several delivery companies—from national giants to regional couriers—and letting technology pick the best one for each specific order.

This approach gives you incredible flexibility and helps you save money on every single shipment. Think of it like booking a flight; you wouldn’t just check one airline. You’d use a search engine to compare prices, routes, and times to find the best deal.

An automated shipping platform can do this instantly. For an order going to a dense city center, a local bike courier might be the fastest and cheapest. For a package headed to a rural address, a national carrier might offer the most reliable service at the lowest cost. The system automatically finds the optimal choice based on real-time rates, delivery speed, and service quality.

This strategy also protects you from service disruptions and allows you to constantly optimize for cost and speed, ensuring you’re never overpaying for shipping.

Returns, or reverse logistics, are often treated as an afterthought. That’s a huge mistake. A clunky or expensive returns process can permanently damage a customer relationship. In contrast, offering simple, hassle-free returns can become one of your most powerful marketing tools.

A smooth returns process builds immense trust. When customers know they can easily send something back, they’re far more confident making a purchase in the first place. In fact, many shoppers will check a store’s return policy before they even add an item to their cart.

Here are a few actionable ways to improve your returns process:

By treating returns as an opportunity to impress rather than a problem to be solved, you can turn a potentially negative experience into a positive one that builds lasting loyalty.

Relying on manual processes for your last-mile deliveries is like trying to navigate a busy city with an old paper map. You might get there eventually, but you’ll waste time, burn extra fuel, and probably make a few wrong turns along the way. Technology is the real-time, intelligent guidance system that makes every delivery faster, cheaper, and far more reliable.

These tools are essential for any multi-channel seller looking to compete. Modern software can automate the complex decisions that bog down your daily operations, freeing you up to focus on growing your business instead of constantly putting out logistical fires.

At its heart, route optimization software does much more than just find the shortest path between two points. Think of it as an expert logistics planner that can juggle multiple constraints at once to create the most efficient schedule possible for your entire fleet.

The software considers factors like:

By crunching all this data in seconds, the software spits out a master plan that minimizes drive time and maximizes the number of successful deliveries each driver can make. This has a direct, positive impact on your Cost Per Delivery and your On-Time Delivery Rate.

For merchants selling across platforms like Shopee, Lazada, and Shopify, the real challenge is fragmentation. You have orders, customer data, and shipping requirements coming at you from all directions. This is where a delivery management platform like OneCart acts as your central command center.

Instead of jumping between multiple seller portals, OneCart pulls everything into a single, unified dashboard. It becomes the single source of truth for your entire fulfillment process, from the moment an order is placed to the second it’s ready for pickup.

Practical example: Imagine your team trying to prepare 100 orders from three different marketplaces. Manually, this means logging into each platform, downloading order lists, and printing shipping documents one by one. With a centralized system, all 100 orders appear in one queue, ready for bulk processing. This simple shift in workflow can save hours of tedious admin work every single day.

This consolidation is the key to unlocking true efficiency in your last-mile operations.

A unified platform gives you powerful tools to solve the challenges we’ve discussed and gain complete control over your fulfillment. For a closer look at how these technologies come together, you can explore comprehensive last mile delivery solutions.

Here’s how specific features translate into smarter last-mile deliveries:

To truly take your delivery operations to the next level, consider how advanced fleet management systems can streamline logistics, track assets, and improve overall efficiency. These systems integrate with management platforms to provide even deeper insights into your delivery performance, from driver behavior to vehicle health. By combining a central command center with intelligent fleet tools, you build a powerful, data-driven foundation for your last-mile success.

Theory is one thing, but a clear plan is what gets real results. Improving your last mile deliveries doesn’t mean you have to rip everything up and start from scratch. Instead, think of it as a straightforward, four-phase roadmap that lets you take back control, iron out the kinks, and build a system that can actually grow with you.

This roadmap—Audit, Strategize, Implement, and Measure—gives you a practical framework for turning what you know into what you do.

Before you can fix a problem, you have to get an honest, clear-eyed look at where you stand right now. This is where those KPIs we talked about earlier become your best friends. It’s time to roll up your sleeves and dig into your data to answer a few critical questions:

This audit phase is about uncovering opportunities. You’re building a baseline so you can measure the impact of the changes you’re about to make.

With your performance audit in hand, you can now build a strategy that targets your weak spots. This is all about picking the right mix of operational tweaks and technology that fits your business and your budget.

For instance, if your audit showed that one carrier is responsible for 80% of your late deliveries in a major city, your strategy could be as simple as testing a new local courier just for that area. Or if you found that manually processing orders is eating up hours and driving up costs, your strategy might be to adopt a platform that can print shipping labels in bulk.

Focus on changes that will deliver the biggest impact with the least amount of disruption. You don’t need to change everything at once. Pick one or two key areas to improve first.

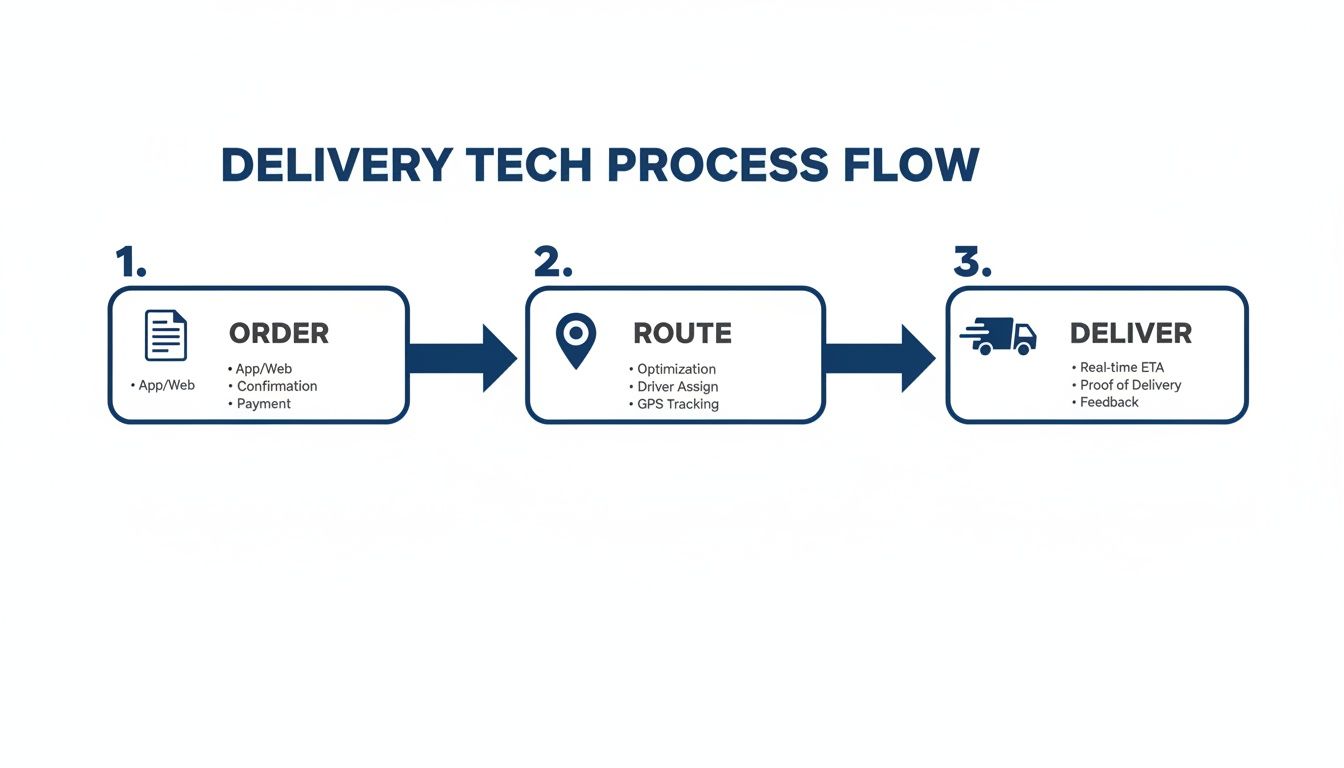

This visual breaks down the basic journey from order placement to the customer’s doorstep—a process that modern technology helps automate.

Every single step here—from an order coming in, to routing it, to getting it out the door—is a chance to make things better.

Now it’s time to put your plan into motion. A smooth rollout is everything, so the trick is to start small. Instead of flipping a switch and moving all your deliveries to a new system overnight, pilot the change in a controlled way.

This approach minimises the risk and lets you work out any kinks before you go all-in. It gives you a chance to learn and adapt without causing chaos.

Finally, remember that optimization isn’t a one-and-done project; it’s a continuous loop. After you’ve rolled out your changes, go right back to your KPIs. Did that new carrier actually improve your On-Time Delivery Rate? Has the new software cut down your Cost Per Delivery?

Use this fresh data to refine what you’re doing. This constant cycle of measuring, learning, and adjusting is what ensures your last-mile strategy keeps getting better over the long haul. A platform like OneCart is built for this very process, centralizing the data and operational tools you need to nail every phase of this roadmap from a single dashboard.

Getting the final step of delivery right can feel like a puzzle. Here are some quick, straightforward answers to the questions we hear most often from online merchants trying to master their last-mile operations.

You don’t need a massive budget to compete on shipping; you just need to be smart about it. The key is to avoid locking yourself into a single carrier. By using a multi-carrier strategy, you can automatically find the cheapest option for every single package, which stops you from overpaying.

Actionable tip: Talk directly with local or regional couriers. They often offer much better rates for specific delivery zones compared to the big national players. You can also offer free shipping but set a minimum order value. This nudges customers to buy more, helping you absorb the shipping cost while still giving them the perk they’re looking for.

Think of your supply chain as a journey with different legs.

Middle mile delivery is the wholesale part of the trip. It’s all about moving goods in bulk—like trucking a large shipment from a central warehouse to a smaller, regional fulfillment hub. The main goal here is efficiency at scale.

Last mile delivery, on the other hand, is the final, personal leg of that journey. It’s when a single package travels from that local hub directly to a customer’s front door. The middle mile moves pallets; the last mile is all about delighting one person at a time.

OneCart supercharges the very first steps of your fulfillment process, which have a massive ripple effect on your last-mile performance. It acts as your operational command center, pulling all your orders from platforms like Shopee, Lazada, and Shopify into one clean dashboard.

This unified view lets your team generate picking and packing lists in a flash, bulk print shipping labels for all your different couriers without juggling multiple seller accounts, and arrange pickups all in one go.

It also syncs your inventory in real-time to prevent overselling, which is a major cause of cancelled orders and unhappy customers. Getting things done this quickly and accurately at the start means packages get to your couriers faster and with fewer errors, setting up your last mile deliveries for success from the get-go.

Ready to take control of your multi-channel operations? OneCart centralizes your orders, inventory, and fulfillment so you can stop juggling platforms and start scaling your business. Learn how OneCart can transform your ecommerce workflow.

Automate & Scale Your Online Business with OneCart

Start a Free TrialUsed by hundreds of merchants in Singapore & Southeast Asia