A Guide to Inventory Management for Small Businesses 2026

Master inventory management for small businesses with our guide. Learn practical strategies, software tips, and scalable techniques to boost profitability.

Master inventory management for small businesses with our guide. Learn practical strategies, software tips, and scalable techniques to boost profitability.

Effective inventory management means knowing exactly what stock you have, where it is, and when you need to order more. It’s the entire process of tracking your products from the moment you buy them from a supplier until they land in your customer’s hands. The goal is to have enough product to meet demand without locking up all your cash in items that just sit on the shelf.

For any small business owner, especially if you’re juggling sales across fast-moving marketplaces like Shopee, Lazada, or your own Shopify store, inventory can feel like a constant battle. Getting it right has a massive, direct impact on your bottom line.

Think of your business as a bucket you’re trying to fill with revenue. Poor inventory management creates holes in that bucket. No matter how many sales you pour in, your profits just keep draining away.

Unmanaged inventory silently kills profits. It shows up as the cost of unsold goods, lost sales from stockouts, wasted marketing spend, and damage to your brand’s reputation when you can’t deliver on a promise.

These profit “leaks” appear in a few key ways that can seriously stunt your business’s health and growth.

Overstocking Waste: This is the classic mistake of having too much of a product. It ties up cash that you could be using for marketing or launching new items. On top of that, you’re paying more for storage and run the risk of products expiring or becoming obsolete. A practical example is a local boutique that over-orders winter coats for Singapore’s climate—that’s cash frozen in useless stock.

Stockout Losses: This is the flip side, where a customer is ready to buy, but you’re out of stock. You lose more than just one sale. That customer will probably head straight to a competitor and might never come back. If this happens often on platforms like Shopee, your store’s ranking can take a hit, making you less visible to future buyers. You can learn more about what a stockout is and how to steer clear of this costly problem.

Administrative Drain: Manually counting stock, trying to reconcile numbers between your different sales channels, and placing frantic, last-minute orders takes up a huge amount of time. This is precious time you should be spending on growing your business, not just trying to keep it afloat.

Proper inventory management is a core strategy for building a resilient, profitable company. A well-organised system transforms your stock from a potential liability into one of your most powerful assets.

For example, a small online store selling handcrafted soaps started out by tracking their sales in a notebook. They were constantly running out of their most popular scents, which led to many frustrated customers.

After they switched to a simple system that tracked their sales data, they could accurately predict which soaps to make more of ahead of a big event like 11.11. As a result, they boosted their revenue by 30% during the sale.

By getting a firm handle on your stock, you free up your cash flow, keep your customers happy, and build a solid foundation to scale your operations without the chaos.

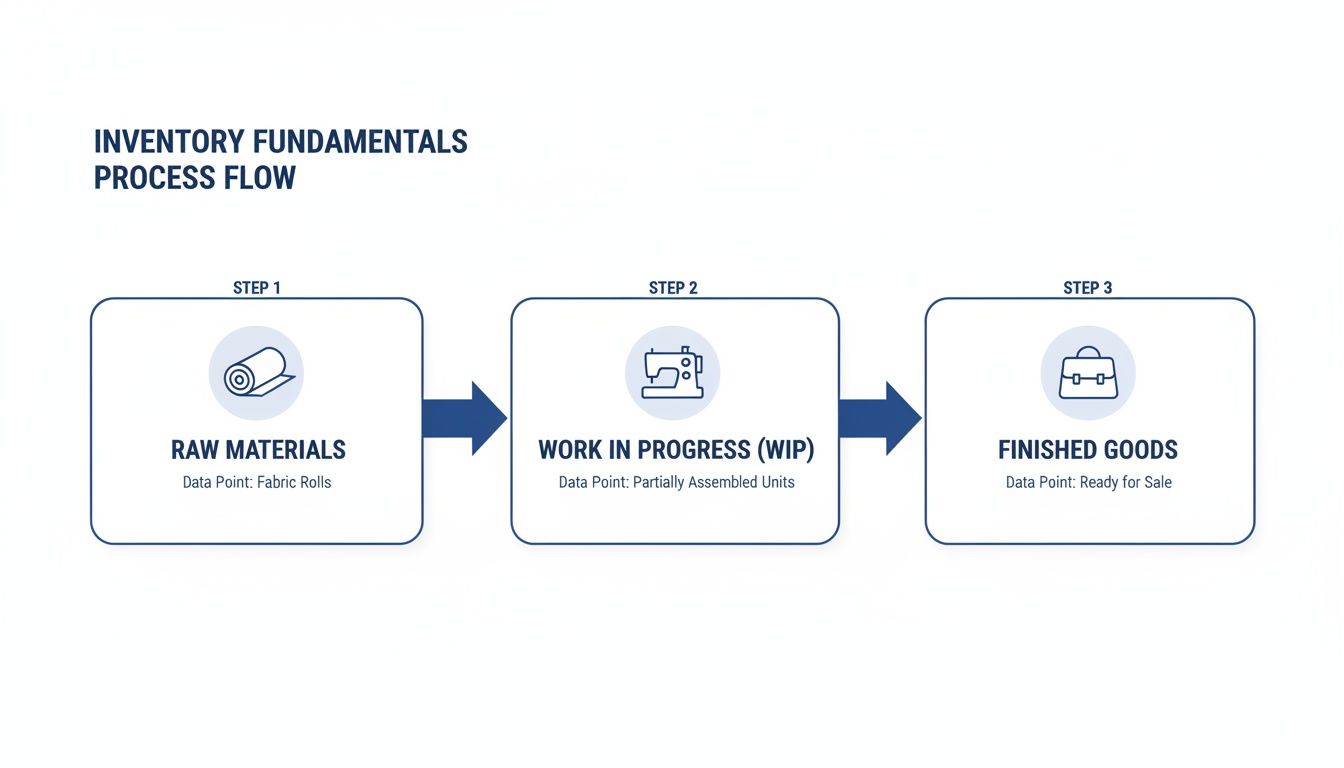

To get a real handle on your stock, you first need to understand what you’re actually working with. Inventory isn’t just one big pile of products waiting to be sold; it exists in different stages, and each one plays a distinct role in your business. Getting these fundamentals right is the first step to smarter inventory management.

Let’s imagine a local artisan who makes and sells handcrafted bags. Their inventory isn’t just “bags.” It’s broken down into three main categories, which helps them see exactly where their money is tied up at any given moment.

Raw Materials: This is the very beginning. For our artisan, this means rolls of fabric, zippers, thread, and buckles. It’s all the components waiting to be turned into something sellable.

Work-in-Progress (WIP): These are the items that have started their journey but aren’t quite ready for a customer. Think of bags that have been cut and sewn but are still waiting for straps or a final lining.

Finished Goods: This is the final stage—the beautiful, handcrafted bags ready to be listed on their Shopify or Shopee store. They’re the products sitting on the shelf, waiting for a new home.

Once you know the types of stock you’re holding, you need a way to measure how well you’re managing it. A few key metrics give you the insights to make profitable decisions instead of just guessing. These numbers tell the story of your inventory’s health.

For many small businesses in Singapore, failing to track these numbers leads to some serious headaches. In fact, a huge number of MSMEs struggle with having too much stock or running out completely, simply because they aren’t using modern inventory practices. Overstocking and poor planning are massive, silent business killers.

Carrying costs are the hidden expenses of holding onto unsold inventory. It’s the total cost of having that product sit on your shelf, gathering dust.

Let’s go back to our bag artisan. Say they have 100 unsold bags, and each one cost $20 to make ($2,000 total value). The monthly carrying cost isn’t zero. It might look something like this:

The total carrying cost here is $95 per month, or 4.75% of the inventory’s value. This proves that unsold stock is actively costing them money every single day.

With a grip on your costs, you can start using proven methods to organise and prioritise your stock. Two of the most effective techniques for small businesses are FIFO and ABC analysis. They sound technical, but they’re simple to understand and put into action.

First-In, First-Out (FIFO): This is a straightforward but powerful principle. The first products you get from your supplier should be the first ones you sell. It’s absolutely crucial for perishable goods, but it’s also a great practice for preventing any item from becoming old, outdated, or obsolete.

Keeping accurate records of all your transactions, especially purchases and sales, is the foundation for understanding your real costs and how your stock moves. Using expense tracking tools like QuickBooks can help you maintain clean financial records for inventory purchases without the fuss.

ABC Analysis: This method helps you prioritise inventory by its value to your business. You categorise items based on how much they contribute to your overall revenue:

For our artisan, a premium leather tote bag might be an ‘A’ item, while a simple cloth pouch is a ‘C’ item. This tells them to focus their counting efforts and reordering vigilance on the totes to avoid missing out on sales. To keep all these items distinct, it’s essential to understand what a SKU number is and how to use it for crystal-clear identification.

Moving past scattered notebooks and messy spreadsheets is a huge step toward getting real control over your business. Building your first proper inventory management system helps organise your operations, slash costly errors, and sets you up to grow without the chaos. The whole process is pretty straightforward, and it all begins with one essential task: finding out exactly what you have right now.

This flow chart shows the basic journey your stock takes, from raw bits and pieces to the final product ready for your customer.

Seeing these stages laid out helps you pinpoint where your cash is tied up at any given moment, which is a game-changer for improving your cash flow.

Before you can build any system, you need a clean, accurate starting line. A full stock audit—also called a physical inventory count—means exactly what it sounds like: physically counting every single item you have in stock. Yes, it can feel like a massive chore, but you absolutely cannot skip this. The goal is to create one single source of truth for your stock levels.

To make this less painful, schedule it during a slow period or after business hours to keep disruptions to a minimum. Get a team on it if you can, assigning specific sections to each person to stop anyone from double-counting.

Once you have your final numbers, you can immediately apply the ABC analysis we talked about earlier. This helps you focus your first system-building efforts on your high-value ‘A’ items—the 20% of products that often bring in 80% of your revenue. Getting those under control first delivers the biggest and fastest win for your bottom line.

With an accurate count in hand, the next job is to create simple, repeatable processes for how your team handles inventory day-to-day. Consistency is everything if you want to stay accurate over the long run. These Standard Operating Procedures (SOPs) don’t need to be some complicated manual; simple checklists usually work best.

Your SOPs should cover three critical moments in an item’s life:

Receiving New Stock: What happens the moment a supplier delivery arrives? Your checklist should include steps like checking the delivery against the purchase order, inspecting for damaged goods, and updating your stock counts immediately in your system (even if it’s just a master spreadsheet for now).

Fulfilling Orders: How do you get products picked, packed, and shipped? Map out the workflow, from printing a picklist to the final scan before you hand it off to the courier. This ensures every order gets the same treatment, cutting down on packing errors and shipping delays.

Processing Returns: What’s the step-by-step process for a returned item? This needs to cover inspecting the product to see if it can be resold, updating the stock count, and getting the customer’s refund or exchange sorted.

A clear, written-down procedure is your best defence against chaos. When every team member knows the exact steps to follow, you eliminate guesswork, prevent mistakes, and make it way easier to train new staff as your business grows.

The final piece of your foundational system is creating a logical way to identify every unique product you sell. This is where Stock Keeping Units (SKUs) and barcodes come in. A well-designed SKU system can turn a chaotic catalogue into an organised, scannable operation.

A SKU is a unique alphanumeric code that you create to identify a product. A good SKU gives you useful information at a glance.

Practical Example:

Let’s say you sell t-shirts. A simple, effective SKU could be TS-BLU-M.

This format is easy for a human to read and instantly tells you key details about the item. From these SKUs, you can then generate barcodes. Barcodes are just the scannable version of your SKUs, letting you use a simple barcode scanner to update stock levels instantly when receiving goods or selling products. This speeds things up dramatically and practically eliminates manual data entry mistakes.

Putting these three elements in place—a full audit, clear procedures, and a solid SKU system—creates a robust foundation for managing your inventory. This organised approach gives you the accuracy and control you need to manage stock effectively, prevent losses, and get your operations ready for whatever comes next.

Picking the right software is a huge decision that can feel pretty overwhelming. But once your business outgrows spreadsheets and scribbled notes, making the right choice is crucial for scaling up without introducing chaos. The goal is to find a platform that fixes today’s headaches and is ready for where you’re headed tomorrow.

So, how do you know you’ve hit that tipping point? The signs are usually pretty clear. Maybe you’re spending hours every week trying to manually sync stock levels between your Shopify store and your Shopee account. Or worse, you’ve lost sales during a flash sale because you sold an item you didn’t actually have. These are classic red flags that a spreadsheet isn’t cutting it anymore.

When you start looking at different options, it’s easy to get distracted by fancy features you’ll probably never use. Focus on the core functions that deliver real value to a growing, multi-channel business. These are the absolute non-negotiables that should be on your checklist.

A great starting point is to explore different types of ecommerce inventory software solutions to get a feel for what modern platforms can actually do. This will give you a solid baseline for comparing what’s out there.

Here are the essentials you should be looking for:

In Singapore’s e-commerce market, where revenue has shot past US$7 billion, the pressure on small businesses during sales events like 11.11 is immense. With carrying costs potentially eating up 20-30% of your inventory’s value each year, efficiency isn’t just nice to have—it’s essential. A platform that gives you a ‘single source of truth’ for all your stock makes all the difference, allowing for instant updates and fast fulfilment when you’re dealing with thousands of daily orders.

The right software for a startup handling 10 orders a day is worlds apart from what a business processing 100 orders a day needs. The best way to choose the right solution is to look at your daily order volume and your business model.

Choosing software is like buying a new pair of shoes. It needs to fit you perfectly right now, but also have enough room for you to grow into. A solution that’s too simple will hold you back, while one that’s too complex will be a costly burden.

To make the decision a bit easier, let’s look at what type of solution makes sense at different business stages.

This table should help you figure out what kind of solution is the right fit based on your daily order volume and what your business really needs at this stage.

| Business Stage | Typical Daily Orders | Recommended Solution | Key Features to Prioritise | Example Scenario |

|---|---|---|---|---|

| Early Stage | 1 - 20 | Advanced Spreadsheets or Basic Inventory Apps | SKU management, simple sales tracking, manual stock updates. | A new seller on TikTok Shop who needs to track a small product catalogue and manually updates stock levels each day. |

| Growing Seller | 20 - 100 | Integrated Inventory Management Software | Real-time multi-channel sync, centralised order processing, basic reporting. | A seller on Shopee and Lazada who keeps overselling and needs a central hub to manage orders and stock automatically. |

| Scaling Business | 100+ | Multi-Channel Commerce Platform | Advanced automation, warehouse management features, demand forecasting, API integrations. | An established brand with its own Shopify site and multiple marketplace stores, needing to streamline warehouse workflows and predict future stock needs. |

By taking an honest look at your current order volume and thinking about where you want to be in six months, you can pick a platform that gives you immediate relief and a clear path forward. This way, your technology becomes something that helps you grow, not something that holds you back.

Selling across Shopee, Lazada, TikTok Shop, and your own website is a fantastic way to reach more customers. But it also throws a huge wrench into your operations. If you’re trying to track inventory manually across all these platforms, you’re setting yourself up for disaster. Overselling becomes almost inevitable, leading to cancelled orders, angry customers, and even penalties from the marketplaces.

The only way to tackle this chaos is to create a ‘single source of truth’ for your stock. Think of it as a central command centre for every item you sell. When a product is bought on Lazada, this central hub instantly updates the available quantity on Shopee, TikTok Shop, and your Shopify store in real-time. This simple shift completely wipes out the risk of selling the same item twice.

Building a single source of truth means you stop splitting your inventory into separate pools for each channel. No more “50 units for Shopee, 50 for the website.” Instead, every platform pulls from one unified count. This doesn’t just prevent overselling; it gives you a crystal-clear, accurate picture of your entire business at a glance.

This unified view is especially critical for businesses here in Singapore. While recent data shows that 47% of small businesses reported growth, they were also hit with rising transport and storage costs. To fight back, 34% made improving their inventory management a top priority. With 63% of small businesses now earning over 10% of their revenue online, a centralised system isn’t just a nice-to-have—it’s essential for managing costs and fuelling growth. You can read the full summary of these findings on Singapore’s small businesses to get a better sense of the landscape.

As you grow, things will inevitably go wrong with shipping. Getting a handle on logistics is non-negotiable, so it’s smart to invest time in understanding shipment exceptions and delays to protect both your inventory and your customer relationships.

Another powerful strategy for multi-channel sellers is creating product bundles or kits. This is where you package several individual items together and sell them as a single product, usually for a better price. Think of a “Skincare Starter Kit” that includes a cleanser, a moisturiser, and a serum.

The trick is making sure your inventory system is smart enough to handle this.

A good system understands that selling one kit means reducing the stock count of each individual component inside it. This is called component-level tracking.

When a customer buys your skincare kit, a proper system automatically deducts one cleanser, one moisturiser, and one serum from your master inventory. This ensures your stock levels for the individual items are always spot-on, preventing you from selling a standalone cleanser when the last one was just sold as part of a kit.

Let’s look at a local Singaporean business, “Crafty SG,” that sells handmade accessories. They started on Shopee but quickly expanded to Lazada and their own Shopify website. At first, they tried managing everything with a spreadsheet, dedicating a set number of items to each sales channel.

It was a nightmare. Their most popular items would sell out on Shopee but still show as available on their website, leading to constant overselling and unhappy customers. The chaos hit its peak during a big 11.11 sale, and the team spent days just trying to reconcile orders and apologise for cancellations.

The turning point came when they switched to a centralised inventory management platform that integrated all three channels. Almost overnight, they had a single, real-time view of their stock. They even created a “New Hobby Kit” bundle, and the system tracked the individual components flawlessly.

The results were immediate. Crafty SG completely eliminated overselling, which sent their marketplace seller ratings soaring. They could finally run flash sales across all channels at once, confident that their stock levels were always accurate. This shift from chaos to control allowed them to stop putting out fires and start focusing on marketing and product development, turning their multi-channel strategy into a real competitive advantage.

Running the day-to-day of a small business, you’re bound to run into some tricky questions about inventory. It’s completely normal.

Let’s clear up some of the most common ones we hear from sellers, with practical advice you can put to use right away.

For your yearly financial reports, a full physical count is usually required once a year. But if that’s the only time you count, you’re flying blind for the other 364 days. Inaccuracies will pile up.

A much smarter approach for day-to-day accuracy is cycle counting.

Instead of a massive, disruptive annual event, you count small sections of your inventory on a rotating schedule. For instance, count your best-selling ‘A’ products every month, and your slower ‘C’ items just once a quarter. It’s less painful, catches mistakes early, and keeps your live inventory data trustworthy.

Sticking with spreadsheets for too long. It’s the most common and costly mistake, especially once you add a second sales channel like Shopee or Lazada. Manual tracking is slow, filled with human error, and completely breaks down during big sales like 11.11. This is where overselling happens.

That small delay between a sale on one platform and you manually updating the stock on another is a recipe for customer frustration. Investing in an affordable, automated system early on saves you from headaches, protects your brand’s reputation, and plugs a major source of lost sales.

Yes, and you absolutely should. This is a must-have for modern retail. Good inventory platforms are built to integrate directly with your Point of Sale (POS) system, creating one unified stock pool for your entire business.

When an item sells in your physical shop, a synchronised system automatically updates the available stock levels on your Shopify, Shopee, and TikTok Shop stores in real-time. This creates a single, accurate source of truth, preventing you from selling an item online that just sold in-store and giving you a complete view of your business’s health.

Think of safety stock as your emergency stash. It’s the extra inventory you keep on hand specifically to avoid stocking out. It’s your buffer against a sudden rush of orders or an unexpected shipping delay from your supplier.

When you’re just starting, a simple rule of thumb is to hold enough safety stock to cover one to two weeks of sales for your most popular items. As you collect more sales data and learn how reliable your suppliers are, you can fine-tune this number. This helps you keep your cash flowing without risking lost sales when things don’t go exactly to plan.

Ready to stop overselling and get a single, real-time view of your entire business? OneCart centralises your inventory, orders, and listings across every marketplace and webstore. Learn how OneCart can streamline your operations and help you grow without the chaos.

Automate & Scale Your Online Business with OneCart

Start a Free TrialUsed by hundreds of merchants in Singapore & Southeast Asia