Master Advanced Shipping Notification to Boost Efficiency and Visibility [2025]

Learn how advanced shipping notification can speed receiving, improve inventory accuracy, and streamline logistics for your business.

Learn how advanced shipping notification can speed receiving, improve inventory accuracy, and streamline logistics for your business.

An Advanced Shipping Notification (ASN) is a digital heads-up from your supplier. It details exactly what’s in a shipment, the precise quantities, and when it’s scheduled to arrive. Think of it as a detailed tracking update for an entire B2B shipment, giving you the complete picture before the delivery truck even pulls up.

Picture this: your warehouse team is preparing for a massive influx of stock right before a big Shopee sale. Suddenly, a huge delivery truck shows up, completely unannounced. Your team has to drop everything and scramble.

They must manually count every item, cross-check them against purchase orders, and hunt for shelf space—all while other urgent tasks are piling up. This chaotic receiving process is slow, full of potential errors, and creates expensive bottlenecks that can bring operations to a halt.

An advanced shipping notification completely changes this scenario. It functions as a digital packing list, sent from your supplier the moment a shipment leaves their facility. This is more than a simple tracking number; it’s a comprehensive file packed with critical data.

Getting this information ahead of time allows your warehouse team to shift from a reactive mode to a proactive, strategic one. They know exactly what’s coming and when it’s due.

This simple heads-up lets them:

This level of preparation is vital in a competitive market. In Singapore’s fast-paced e-commerce scene, sellers on platforms like Shopee, Lazada, and TikTok Shop must manage huge order volumes. With record port activity, the ASN has become an essential tool for staying efficient. Singapore’s port has seen massive growth in container traffic, underscoring the need for streamlined logistics.

Ultimately, the advanced shipping notification is a cornerstone of modern supply chain management. It makes your entire fulfillment process more predictable, visible, and efficient—a massive advantage for any growing business.

Understanding its role is the first step to mastering your entire warehousing and logistics operation.

An Advanced Shipping Notification (ASN) is the detailed blueprint of an incoming delivery. When you break it down, you’ll find a set of core components, each with a specific, practical purpose. Understanding these data fields is the first step in turning your receiving dock from a place of chaotic reaction to one of proactive control.

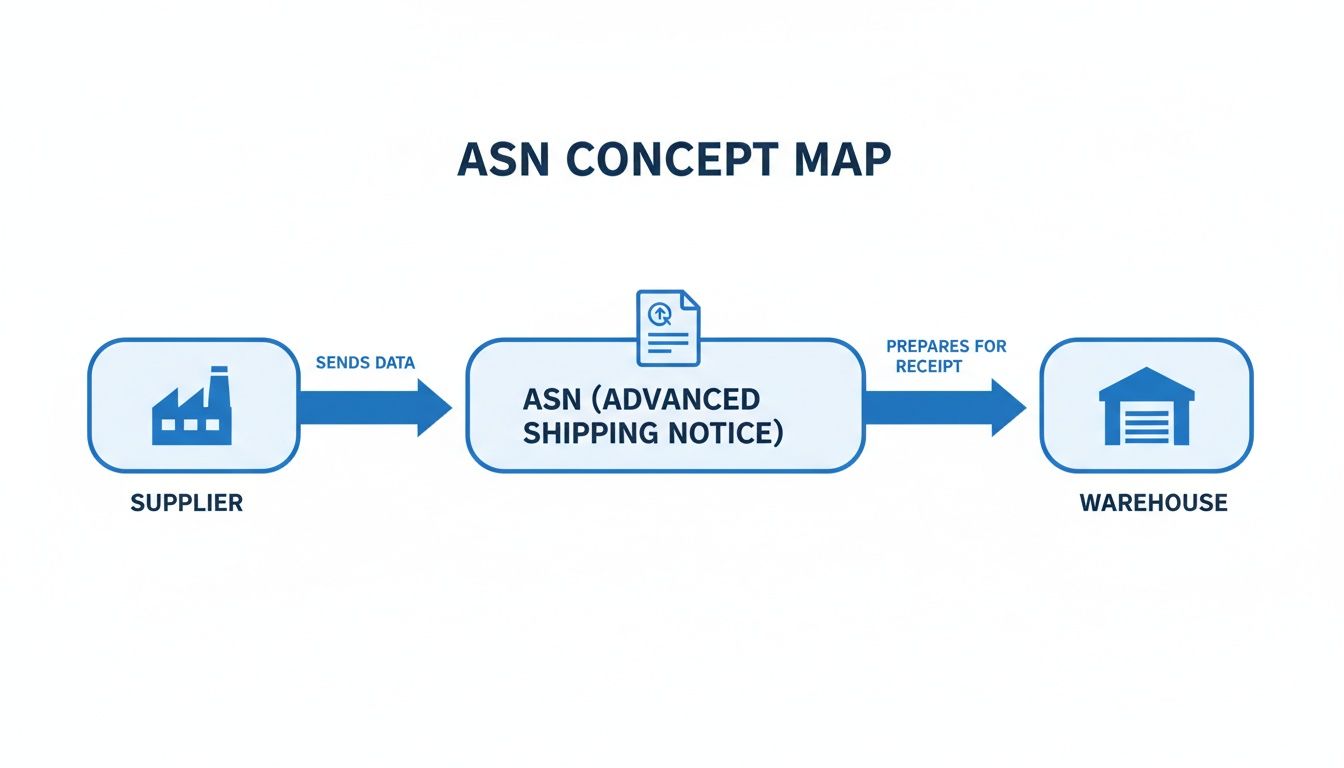

This visual shows the simple yet powerful flow of information in the ASN process, starting from the supplier’s initial shipment all the way to the final prep at your warehouse.

This digital handshake ensures your team has all the necessary details long before a single box arrives, paving the way for a much more organized and efficient workflow.

To understand what’s inside an ASN, it helps to break down the key data fields and see why each one matters for your warehouse operations. This table lays out the crucial pieces of information you’ll find in a typical ASN and explains their direct impact on efficiency and planning.

| Data Field | Description | Why It’s Important for Your Warehouse |

|---|---|---|

| Purchase Order (PO) Number | The unique ID that links the shipment back to the original order placed. | Allows for instant verification upon arrival. Your team can quickly scan and match the delivery to the correct PO, ensuring you’re getting exactly what you paid for. |

| Product Details | A granular breakdown of the items, including SKUs, descriptions, and quantities. | Essential for inventory accuracy. Knowing the exact count of each item lets you update your stock levels immediately, preventing overselling and stockouts. |

| Shipment Information | Details about the logistics, such as the carrier’s name, tracking number, and the estimated date and time of arrival (ETA). | Crucial for scheduling labor. You can align staff shifts with the delivery ETA, avoiding unnecessary overtime or delays caused by being short-staffed. |

| Packaging Specifics | Information on how the goods are packed—e.g., number of pallets, cartons per pallet, and units per carton. | Drives physical preparation at the dock. It tells your team what equipment (like forklifts) to have ready and how much space to allocate for the incoming goods. |

By providing a clear, detailed breakdown of the shipment’s contents and structure, the ASN allows for precise planning. This foresight separates a smooth, cost-effective receiving process from a costly, labor-intensive one.

Let’s put this into a real-world scenario. Imagine you’re an e-commerce manager preparing for the massive 11.11 sale on Lazada. You’ve ordered a huge shipment of your best-selling wireless earbuds from a supplier in China. When they dispatch the order, they send you an ASN.

With this detailed file in hand, your 11.11 prep becomes far more strategic. The PO number confirms the order’s legitimacy. The SKU-level quantities—say, 5,000 units of black earbuds and 3,000 white ones—let you update your Lazada store’s inventory levels accurately. The carrier details help you track the shipment in real-time and manage your team’s schedule effectively.

Finally, the packaging information ensures the physical receiving process is seamless. If the ASN says the order is arriving on 10 pallets, with 80 cartons per pallet and 10 units per carton, your team can get ready. They can allocate a specific staging area for the incoming pallets and have the forklift on standby. They can even pre-print labels and prepare the exact shelving locations, drastically cutting down the “dock-to-stock” time.

This means your best-selling earbuds are available for sale faster, maximizing your revenue potential during the peak shopping season. Beyond the ASN itself, understanding other critical shipping documentation, such as a consignment note, can further clarify the data points involved in efficient logistics. This comprehensive view of shipping documents helps build a more resilient and informed supply chain operation.

Understanding the technical parts of an advanced shipping notification is a good start, but the real value is its impact on your business. Adopting ASNs is a strategic move that unlocks tangible benefits that flow straight to your bottom line.

This includes faster receiving, pinpoint accuracy, smoother supplier relationships, and significant cost savings.

The most immediate win is a massive boost in operational speed. When your warehouse team knows exactly what’s in a shipment before it pulls up to the dock, they can prepare everything in advance. This eliminates the chaotic scramble of unplanned deliveries.

Instead of your team manually counting and checking items one by one against a paper invoice, they can scan a barcode and check in entire pallets in minutes. This single change can slash receiving times by up to 75%. That’s a huge efficiency gain, freeing up your staff to focus on what actually makes you money—fulfilling customer orders—instead of getting bogged down at the loading bay.

One of the biggest challenges for any online seller is keeping stock levels accurate across multiple channels. An ASN gives you the data to update your inventory management system the moment goods leave the supplier—not when they’re finally counted and put on a shelf hours or days later.

This early visibility is a powerful way to prevent overselling, especially when you’re running promotions for popular products on platforms like TikTok Shop or Lazada.

Practical Example: Preventing Overselling on TikTok Shop Imagine you’re running a flash sale on a popular beauty product. Your supplier sends an ASN for a shipment of 1,000 units that’s on its way. Even though the physical stock hasn’t arrived, you can update your inventory system to show these 1,000 units as “incoming.” This allows your e-commerce platform, powered by a system like OneCart, to confidently accept orders against this future stock, maximizing sales without the risk of overselling and disappointing customers.

This precision means the stock figures on your storefronts are a true reflection of what you have on hand and what’s in transit. Accurate inventory leads to happier customers, fewer cancelled orders, and a brand people trust.

Manual processes are slow, expensive, and prone to error. The hours your team spends physically counting items, matching them to paper purchase orders, and fixing discrepancies add up quickly. An ASN automates a large part of this work.

By feeding ASN data directly into your warehouse management system (WMS), you cut down on manual data entry. This minimizes the risk of human error that leads to costly mistakes, like miscounting items or accepting the wrong products. The result is a much smoother workflow that requires less hands-on effort, directly lowering your labor costs for every single shipment you receive.

ASNs also enable more advanced logistics strategies that can give you a serious competitive edge. One of the most powerful is cross-docking.

Cross-docking is a logistics technique where incoming goods from a supplier are immediately sorted and sent out to fulfill customer orders, completely bypassing storage. This is only possible if you have the precise, advance information an ASN provides.

This strategy is incredibly effective for fast-moving products. It slashes storage costs, minimizes handling, and can shrink order fulfillment times from days down to just a few hours.

In a hyper-efficient logistics hub, implementing strategies like this is essential. For the 12th year running, Singapore has been named the top international shipping centre, a testament to its world-class maritime services and infrastructure. This ranking underscores why modern DTC brands and 3PLs must use tools like ASNs to forecast and manage their port interactions with precision.

You’re convinced of the benefits of Advanced Shipping Notifications. The next question is, how do you actually implement them in your business?

Bringing ASNs into your daily operations is a project that needs thoughtful planning, good collaboration with your partners, and the right tools for the job. Starting now is how you prepare your business to handle serious growth without the usual operational headaches.

First, you need to figure out the different ways you can receive ASN data. The method you choose will depend on your technical know-how, your budget, and what systems your suppliers are already using.

Not every business needs a complex, fully automated system right away. The key is to pick a format that fits your needs today but can also scale as your order volume grows.

Here are the common options:

Actionable Insight: If you’re a growing Shopify brand, a great low-cost strategy is to start with CSV uploads from your top three suppliers. It lets you test the benefits without a big investment. As your order volume climbs, you can then look into API integrations to automate things and cut down on manual entry.

Successfully rolling out an ASN program requires a solid, structured plan. Breaking it down into manageable steps ensures a smoother process for both your team and your partners.

1. Team Up with Your Key Suppliers Your ASN system is only as good as the data your suppliers send you. Start by identifying your most critical suppliers—the ones you order from most often or in the largest volumes. Discuss your plan to use ASNs with them, and be sure to highlight the benefits for them, like faster payments and fewer disputes over shipment contents.

2. Nail Down Your Data Requirements Next, decide what information is non-negotiable for every ASN. As a bare minimum, you’ll need the Purchase Order (PO) number, SKUs, quantities, and carrier tracking information. Create a simple template or data sheet to give your suppliers so everyone is on the same page.

3. Pick the Right Tech Based on your business size and your suppliers’ capabilities, choose the best format (CSV, API, EDI). If you’re already using an order management system (OMS), check what it supports. Many modern platforms are built to receive ASN data and use it to automate your receiving process.

4. Test, Test, and Test Again Before you go live, run a few pilot tests with a cooperative supplier. Ask them to send test ASNs for a couple of shipments. Your team should then use this data to do a dry run of the receiving process, from checking the data’s accuracy to scanning the goods as if they just arrived. This is your chance to find and fix any technical issues or process gaps before they cause real problems.

5. Get Your Warehouse Team on Board This is a critical step. Your warehouse crew needs to understand what an ASN is, why you’re implementing it, and how it will change their daily work. Show them how this new process makes their job easier by cutting out tedious manual counting and guesswork. Provide clear, hands-on training with any new software or scanners to build their confidence. A well-trained and motivated team is what will truly unlock the power of your new ASN workflow.

Getting an advanced shipping notification system running is a huge step forward, but it’s rarely a straight line from launch to perfection. The real world often presents challenges, from inaccurate data and technical hiccups to simple human error. The key is to anticipate these challenges and have a game plan ready.

Nailing this part of the process separates a frustrating project from a genuine strategic advantage. It makes your entire receiving operation stronger and more reliable.

The most common headache is receiving an ASN where the data doesn’t match what’s on the pallet. Wrong quantities, incorrect SKUs, or missing items happen. When they do, the ASN creates more work instead of less.

To get ahead of this, you need a way to track supplier performance. It doesn’t need to be a complex system.

This approach transforms the dynamic. Instead of just pointing out problems, you’re working together to fix them, strengthening your supplier relationships and improving data quality at the same time.

Getting your systems to communicate with your suppliers’ systems can be challenging. Mismatched data formats, failing APIs, or conflicts with your own ERP can stop an ASN in its tracks, causing serious delays.

Having a solid technical strategy is your best defense. It’s often worth looking into solutions for mastering ERP integration to make sure your core system can communicate effectively with others.

Actionable Insight: Don’t try to connect with every supplier at once. That’s a recipe for disaster. Instead, run a pilot program with one or two of your most tech-savvy partners. This lets you iron out all the kinks in a controlled setting, creating a proven template you can confidently roll out to everyone else.

A phased rollout and thorough testing are key to avoiding major integration headaches.

Sometimes, even with a flawless ASN, things go wrong. A pallet gets damaged in transit or a picking error occurs at the supplier’s end. What matters is having a clear, standardized process for what your team should do the moment they find a mismatch between the physical count and the ASN.

Your team needs to know the drill:

A well-defined protocol empowers your team to solve problems quickly, stopping small errors from turning into major warehouse disruptions. Given the state of global logistics, this kind of precision is more critical than ever. Port delays have surged worldwide, with major hubs like Singapore facing serious congestion. Every minute you save with a smooth receiving process is a win.

Got questions about ASNs? You’re not alone. When businesses start looking into Advanced Shipping Notifications, a few practical questions always pop up. Let’s tackle the most common ones head-on.

It’s easy to confuse these two, but they serve completely different purposes. Think of an Advanced Shipping Notification (ASN) as the detailed packing list your supplier sends you before the truck leaves their warehouse. It’s an operational tool, telling your team exactly what’s coming, down to the quantity of each item. This lets you plan your receiving, clear space, and get ready.

A Bill of Lading (BOL), on the other hand, is a legal document. It’s the official contract between the shipper and the logistics company. It acts as a receipt and is the title document needed to claim the shipment.

In short, the ASN helps you plan your warehouse operations, while the BOL legally transfers ownership of the goods.

Absolutely. Starting early is a huge advantage. As your small business grows, managing incoming stock quickly becomes a major bottleneck to growth.

Even a simple ASN system—like using CSV files from your key suppliers—professionalizes your receiving process from day one. It lets you update your stock levels on platforms like Shopify or Shopee the moment goods arrive, which is crucial for preventing overselling during a big sale. It also means your team isn’t stuck doing tedious manual counts, freeing them up to focus on getting customer orders out the door.

Putting ASNs in place early builds a scalable foundation that you’ll be thankful for later.

The key is to frame it as a win-win, not just another demand. Nobody likes more administrative work, so you need to show them what’s in it for them.

Explain to your suppliers that when they send an ASN, you can process their shipments much faster. Faster processing often leads to quicker payment cycles for them—a benefit every business understands. It also reduces disputes over what was sent versus what was received, since everything is documented upfront.

A Practical Tip: Start Small Don’t try to onboard all your suppliers at once. Instead, start with your top one or two partners—the ones you rely on the most. Make it incredibly easy for them. Give them a simple template to fill out. By positioning it as a step toward a stronger, more efficient partnership, you’ll get much better buy-in.

Once you have a couple of success stories, you can use that as a case study to bring your other suppliers on board.

To know if your ASN system is working, you need to track the right numbers. These key performance indicators (KPIs) provide the hard data to prove the value ASNs are bringing to your operations.

I’d suggest focusing on these three:

Tracking these metrics doesn’t just justify the initial setup effort; it also shows you exactly where you can keep tweaking and improving your supply chain.

Ready to stop overselling and streamline your warehouse operations? OneCart centralises your inventory and orders from Shopee, Lazada, TikTok Shop, and more, giving you a single source of truth. See how you can achieve ROI in days by visiting https://www.getonecart.com.

Automate & Scale Your Online Business with OneCart

Start a Free TrialUsed by hundreds of merchants in Singapore & Southeast Asia