A Guide to 3rd Party Logistics for Ecommerce Brands [2026]

Discover how 3rd party logistics (3PL) can scale your ecommerce brand. This guide covers benefits, costs, and choosing the right partner to grow your business.

Discover how 3rd party logistics (3PL) can scale your ecommerce brand. This guide covers benefits, costs, and choosing the right partner to grow your business.

If you’ve ever found yourself buried in packing tape and shipping labels as your online store grows, you’ve hit a common ecommerce scaling problem. This is exactly where third-party logistics, or 3PL, comes in.

A 3PL is an expert operations partner for your business. You outsource the physical side of your ecommerce fulfilment—storing products, managing inventory, picking orders, packing boxes, and shipping them—to a specialized company. This frees you up to focus on activities that grow your brand, like product design, marketing, and customer service. It’s a strategic move that lets you scale without needing to lease a warehouse or hire your own fulfillment team.

Imagine trying to run your online store while personally managing a warehouse, packing every single order, and standing in line at the post office. This might work when you’re starting out, but it quickly becomes unmanageable as your brand grows. A third-party logistics (3PL) provider is a company that handles this entire operational process for you.

This is a massive industry that powers global ecommerce. The 3PL market was valued at USD 1.29 trillion in 2023 and is projected to nearly double by 2032. This growth shows how essential these partners have become for brands building an efficient supply chain.

At its core, a 3PL acts as an extension of your team. Their job is to handle everything that happens after your customer clicks “buy.” When an order comes in from your Shopify store or Shopee shop, it’s sent to your 3PL’s system. From there, their team takes over the entire physical process of getting that product to your customer’s doorstep.

A good 3PL offers a suite of services designed to cover the complete order fulfilment lifecycle. While specifics can vary, most providers handle a core set of tasks essential for any serious ecommerce business.

Here’s a look at the essential services a 3PL provider typically handles, turning the complex process of logistics into a smooth operation for you.

| Core Functions of a 3rd Party Logistics Provider | ||

|---|---|---|

| Service Area | What It Involves | Key Benefit for Sellers |

| Receiving & Warehousing | Accepting your incoming inventory from suppliers, inspecting it for accuracy and damage, and securely storing it in their fulfillment centers. | You don’t need your own warehouse space or the staff to manage it. |

| Inventory Management | Using software to track your stock levels in real-time, ensuring you know exactly what’s available to sell across all your channels. | Prevents overselling, provides clear data for reordering, and gives you a single source of truth for your stock. |

| Picking & Packing | When an order arrives, their team locates the items (“picking”) and packs them according to your brand’s specifications, ready for shipment. | Ensures orders are fulfilled accurately and professionally without you needing to do it yourself. |

| Shipping & Distribution | Managing relationships with multiple shipping carriers (like DHL, FedEx, or local couriers) to find the best rates and delivery speeds for each order. | Taps into bulk shipping discounts you couldn’t get on your own, saving you money and improving delivery times. |

These functions work together to create a seamless flow from the moment an order is placed to the moment it arrives with your customer.

Actionable Insight: If you spend more than two hours a day on fulfilment tasks, or if your living room has become a makeshift warehouse, it’s time to look for a 3PL. Every hour you spend taping boxes is an hour you are not spending on marketing or product development.

For sellers on fast-moving platforms like TikTok Shop or Lazada, sudden growth can break your operations. One viral post can lead to an avalanche of orders you’re not equipped to handle. A 3PL is built to solve these problems.

Practical Example: Your brand is running a huge 11.11 sale. Overnight, you get 1,000 orders—far more than your small in-house team can pack and ship in a day. With a 3PL, this surge is business as usual. They have the staff, space, and automated systems to process that volume efficiently, ensuring your customers get their orders on time and preventing a flood of negative reviews.

This is the real power of effective warehousing and logistics. By outsourcing these complex, capital-intensive tasks, you avoid the headaches of warehouse leases, hiring and training staff, and negotiating shipping contracts. You can focus on what you’re best at: building a fantastic brand that people love.

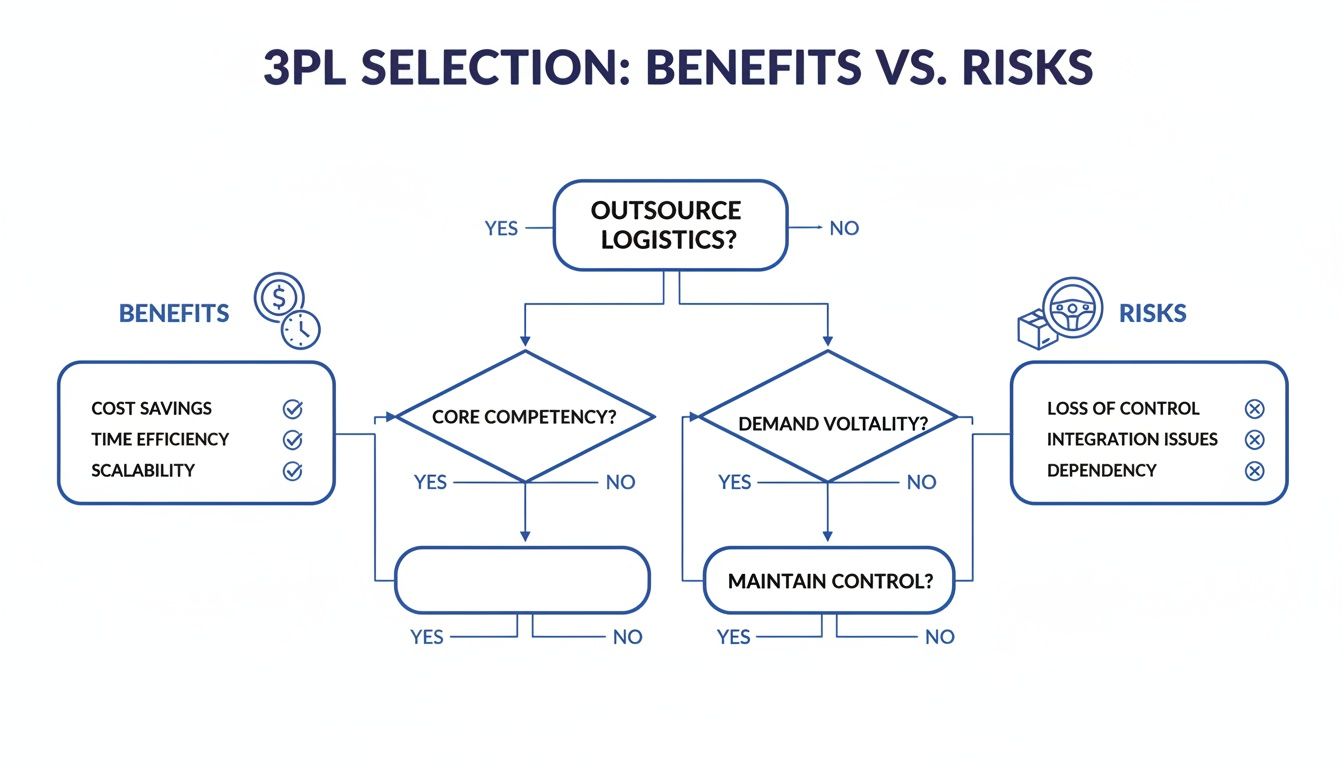

Deciding to hand your logistics over to a 3rd party logistics provider is a huge step for any ecommerce brand. On one hand, it can unlock growth and efficiency that would be impossible to achieve on your own. On the other, you’re trusting another company with a critical piece of your customer experience. It is important to understand both sides.

The most immediate benefit is getting access to a world-class logistics operation without the significant upfront investment. You can forget about leasing a warehouse, hiring staff, and negotiating shipping contracts. You just tap into your 3PL’s established network, instantly making your operations more professional and ready to scale.

Partnering with the right 3PL brings real, tangible advantages that directly improve your bottom line and make your customers happier. These benefits go beyond simply not having to pack boxes in your garage.

Cost and Time Savings: A good 3PL operates on economies of scale. Because they ship massive volumes for hundreds of clients, they get heavily discounted shipping rates from carriers—rates a single brand could never secure. For example, sending a small parcel might cost you $10 on your own, but a 3PL’s bulk rate might get that down to $6, a 40% savings they pass on to you.

Faster Delivery Times: Most quality 3PLs run a network of warehouses in strategic locations. If you’re based in California but have a ton of customers in New York, a 3PL with an East Coast facility can stock your inventory there. This shrinks shipping time from a 5-day cross-country trip to a 1-2 day local delivery. That speed can dramatically improve the customer experience and boost your conversion rates.

Focus on Business Growth: Every hour you spend managing inventory, packing orders, or dealing with shipping carriers is an hour you’re not spending on marketing, product development, or customer service. Offloading fulfillment lets you and your team concentrate on the activities that grow your brand and bring in revenue.

Outsourcing fulfillment can help businesses reduce logistics costs by an average of 11% while improving customer service. A 3PL is an investment in efficiency and a better brand experience.

While the benefits are compelling, handing over the keys to your inventory and fulfillment introduces some real risks. Being aware of these challenges from the start is the best way to tackle them.

The most significant risk is a loss of direct control. Your products and your unboxing experience are in someone else’s hands. If the 3PL makes a mistake—like shipping the wrong item or using poor packaging—it’s your brand’s reputation on the line.

Another common worry is inventory visibility. Without the right technology, you can feel disconnected from your own stock levels, making it difficult to forecast demand or manage reorders. This is why choosing a tech-forward partner is essential. If you want to dive deeper into different logistics models, our article comparing 3PL vs 4PL providers offers more detail.

A successful 3PL relationship comes down to setting clear expectations and maintaining open communication. Here are a few actionable steps to protect your business and build a smooth partnership.

Establish a Detailed Service Level Agreement (SLA): Your contract needs to spell out performance expectations clearly. Specify key metrics like order accuracy rate (e.g., 99.8%), dock-to-stock time (e.g., inventory must be processed within 48 hours of arrival), and on-time shipping targets. This document is your best tool for holding your partner accountable.

Prioritize Technology and Integration: A modern 3PL must offer a robust software platform that gives you real-time visibility into your inventory and order status. Ensure their system integrates seamlessly with your ecommerce platforms (like Shopee) to automate the flow of orders and eliminate manual data entry errors.

Define Quality Control Checks: Don’t leave your brand’s unboxing experience to chance. Provide your 3PL with clear, visual instructions on how to pack orders, when to include marketing inserts, and any other brand-specific touches. Actionable Tip: Schedule regular check-ins and send “mystery shopper” orders to yourself to see the quality of their work firsthand.

Picking a 3rd party logistics partner is one of the most critical decisions for your growing e-commerce business. This is more than renting warehouse space; you’re choosing an operations partner who will directly impact your customer experience, brand reputation, and bottom line. A methodical approach, focusing on criteria that matter for your brand, is the best way to succeed.

The process starts with a deep dive into your own business. Before you contact potential 3PLs, you need to know your operational details. Where do most of your customers live? What are your order volumes, and what do they look like during your busiest seasons? This data will guide your selection process.

In today’s e-commerce world, a 3PL without a solid tech stack is ineffective. Their software is the central nervous system of your fulfillment operation. Its ability to connect seamlessly with your sales channels is completely non-negotiable.

If you sell on Shopify, your 3PL needs a rock-solid, direct integration. The same goes for marketplaces like TikTok Shop or Shopee. Manual processes can lead to overselling, shipping errors, and hours of administrative work. You need a partner whose system can automatically pull in orders, update inventory levels in real-time across every channel, and push tracking information back to your stores without manual intervention.

This flowchart helps visualize the core trade-offs. You’re weighing the clear benefits of cost savings and scalability against the real risks of losing direct control and becoming overly dependent on a single provider.

A great partnership strikes a balance where the efficiency gains far outweigh the loss of direct oversight. You achieve this through smart contracts, clear communication, and robust technology.

A 3PL’s physical footprint directly impacts your shipping costs and delivery speeds. A single warehouse might be fine if your customers are all in one region, but for a national brand, a multi-warehouse network is a game-changer.

Practical Example: Say you ship everything from a warehouse in Los Angeles. An order going to New York might take five days to arrive and cost you $15. Now, imagine your 3PL also has a warehouse in New Jersey. They can fulfill that order locally, cutting delivery time to two days and dropping the shipping cost to perhaps $8. That’s a huge win for both your budget and your customer’s satisfaction.

Actionable Tip: When vetting a 3PL, ask them for a “shipping zone analysis.” Give them a sample of your anonymized order data and have them show you exactly how their warehouse network would lower your average shipping zone and cost per order. This data-driven approach provides concrete numbers instead of just a sales pitch.

3PL pricing can be confusing, and hidden fees can hurt your margins if you’re not careful. A transparent partner will give you a clear, itemized quote that breaks down every charge. Don’t just look at the pick-and-pack fee; you need to examine every line item.

Here are some common fees to watch out for:

Beyond cost, you must verify their performance. Ask for their standard Service Level Agreement (SLA) and look for hard numbers. You want to see metrics like an order accuracy rate of 99.8% or higher and a dock-to-stock time of 48 hours or less. These are promises that directly affect your customers.

Once you have a shortlist of potential partners, it’s time to get specific. Generic questions will only get you generic answers. You need to ask tough, scenario-based questions that reveal how they operate under pressure.

To help you get started, here’s a checklist you can use to structure your conversations and compare providers.

Use this checklist to go beyond the sales pitch and systematically compare your top candidates to see who truly aligns with your business needs.

| Evaluation Criteria | What to Look For | Key Questions to Ask |

|---|---|---|

| Technology & Integration | Direct, real-time integrations with your sales channels (Shopify, Amazon, etc.). A user-friendly dashboard for visibility. | “Can you demo your Shopify integration? How does your system handle inventory updates across multiple channels in real time?” |

| Operational Performance | Clear Service Level Agreements (SLAs) with metrics for accuracy (99.8%+), receiving (48 hours), and shipping. | “What are your guaranteed SLAs for order accuracy and dock-to-stock time? What happens if you miss them?” |

| Scalability & Flexibility | Ability to handle your peak season volumes without a drop in service. Staffing plans for unexpected surges. | “Walk me through how you handled a client’s Black Friday surge last year. How do you scale your team and resources?” |

| Returns Management | A well-defined, efficient process for handling returns, inspections, and restocking. Clear pricing for each step. | “What is your end-to-end returns process? What are the specific costs for receiving, inspecting, and restocking an item?” |

| Onboarding & Support | A structured onboarding plan with a dedicated point of contact. Accessible and responsive customer support. | “What does your typical onboarding process look like, from first shipment to first live order? Who will be my dedicated account manager?” |

| Inventory Management | Strong processes for managing damaged or lost inventory. Clear liability and insurance coverage. | “What is your process for handling inventory that arrives damaged from my supplier? What is your policy for items lost or damaged in your warehouse?” |

Asking these detailed questions forces potential partners to show their operational competence, not just their sales skills. It’s the best way to find a partner who can truly support your growth.

To get the most out of a partnership with a 3rd party logistics provider, you need to understand their data. Getting a grip on the key costs and performance metrics is about protecting your profit margins and ensuring your customers get the experience they deserve.

Your 3PL is the engine of your fulfillment operation. The costs are the fuel required to keep it running, and the key performance indicators (KPIs) are the gauges on the dashboard telling you how well that engine is performing. You have to watch both to stay on track.

When you get a quote from a 3PL, it can be a long list of charges. Let’s break down the most common fees so you can analyze any proposal with confidence and avoid surprise costs that can eat into your profits.

Receiving Costs: This is what you pay for your 3PL to accept your inventory. It covers the labor for unloading stock, inspecting it for damage, counting it to match the packing slip, and logging it into their warehouse management system (WMS). This is usually billed per hour, per pallet, or per carton.

Storage Costs: This is the rent for the physical space your products occupy in the warehouse. It’s typically billed monthly and calculated per pallet, per bin, or by the cubic foot. Watch for “long-term storage” fees—some 3PLs charge extra for inventory that sits for several months, incentivizing efficient stock management.

Pick and Pack Costs: This is the core of the fulfillment fee, covering the work of picking items from shelves and packing them into boxes. This can be a flat fee per order, a fee per item picked, or a mix. For example, a 3PL might charge $2.00 per order plus $0.35 for each additional item in that order.

Shipping Costs: This is the postage charge, which the 3PL passes on to you. Because they ship in massive volumes, 3PLs get significant discounts from carriers like FedEx or DHL and pass a portion of those savings on to their clients. This is often one of the biggest financial benefits of using a 3PL.

Costs tell you what you’re paying, but KPIs tell you what you’re getting for your money. These metrics are the vital signs of your fulfillment health and are directly linked to customer satisfaction and loyalty. Any solid 3PL partner will provide a dashboard where you can monitor these in real-time.

A high-performing 3PL should be viewed as a growth partner, not just an expense. When your on-time shipping rate is high and your order accuracy is nearly perfect, you spend less time dealing with customer service issues and more time winning new business.

Here are the non-negotiable KPIs to watch:

Order Accuracy Rate: This measures the percentage of orders shipped without any errors (like the wrong item or wrong quantity). The industry benchmark is 99.8% or higher. A dip here leads to unhappy customers and expensive returns.

On-Time Shipping Rate: This tracks the percentage of orders that are picked, packed, and handed off to the shipping carrier within the agreed-upon window (usually within 24 hours). This is critical for meeting customer delivery expectations.

Dock-to-Stock Time: This is how long it takes for your 3PL to receive your incoming inventory and make it available for sale. A good target is 24-48 hours. The faster this happens, the sooner your products are ready to sell, reducing the risk of stockouts.

The global stage for 3rd party logistics is growing rapidly, with some regions leading the way. The Asia Pacific market, for example, is a powerhouse, holding over 51% of the global market share. This boom is fueled by the explosive growth of ecommerce on platforms like Shopee and TikTok Shop, creating incredible demand for smart warehousing and fulfillment. You can discover more about these global 3PL market trends and how they impact sellers.

Choosing a 3rd party logistics provider is a huge milestone, but the real work starts after you sign the contract. A successful partnership is more than just handing over your inventory. It’s about active collaboration and clear communication that turns a vendor relationship into a strategic alliance for your brand.

It all begins with a meticulous, well-planned onboarding process.

The foundation for a smooth transition is an accurate inventory audit. Before you ship a single box to your new partner, do a full physical count of your stock to ensure your records are perfect. This simple step prevents frustrating discrepancies later and gives both teams a clean, reliable baseline.

Once your stock arrives at their facility, the next critical move is to run a series of test orders. Don’t wait for real customers to be your test subjects. Send a few orders to yourself or your team members to verify that the systems are synced correctly, the packaging meets your brand standards, and the shipping times are what you expected.

Once you’re live, the focus shifts from setup to sustained performance. A proactive approach is everything. Don’t wait for problems to arise; build a regular communication cadence to keep your teams aligned and always looking for ways to improve.

For seamless operations, it’s also crucial to consider the critical ERP integration steps for Shopify stores to ensure data flows efficiently between all your systems. This helps maintain a single source of truth for orders and inventory.

A great way to manage the relationship is through structured, regular check-ins.

A successful 3PL relationship is a two-way street. The brands that see the best results are the ones who treat their logistics provider like an extension of their own team, sharing forecasts, upcoming marketing plans, and new product launch details well in advance.

This level of collaboration moves your partnership beyond transactions. When your 3PL understands your business goals, they can offer valuable insights and proactively adjust their operations to support your growth. You can explore how an order management system (OMS) helps centralize this data for even smoother collaboration.

Deciding whether to bring in a logistics partner can feel like a huge step, so it’s natural to have questions. Let’s tackle some of the most common ones we hear from ecommerce sellers and operations managers.

The signal is when fulfillment starts taking time away from activities that grow your business. If you’re spending hours every day packing boxes instead of working on marketing, talking to suppliers, or developing new products, you’re hitting the limit of what you can do on your own.

A few classic signs include running out of storage space, being unable to keep up with orders during a big sale, or noticing an increase in shipping mistakes. As a practical rule of thumb, if you’re consistently shipping 50 or more orders per day, it’s a strong sign you should start seriously looking at 3PL options to scale without burning out.

Most modern 3PLs connect to your stores using APIs, but for sellers on multiple channels, the smarter move is to use a central multi-channel management platform.

This approach simplifies everything. You connect all your stores—Shopee, Lazada, Shopify, and TikTok Shop—to one central hub. That hub becomes your single source of truth for all your inventory and orders. Then, you only need to build one simple integration: from that platform to your 3PL.

This setup prevents you from overselling stock you don’t have and ensures every single order, no matter where it came from, is sent to your 3PL for fulfillment automatically, eliminating manual data entry.

Actionable Insight: Think of a centralized platform as the universal adapter between all your sales channels and your 3PL. It automates the entire information flow, reducing manual work and dramatically cutting down the risk of errors that can damage your customer experience and brand reputation.

You have to carefully review the fee schedule in any 3PL proposal. There are a handful of common costs that are easy to overlook, and they can seriously affect your margins if you aren’t ready for them.

Keep an eye out for these specific line items:

A good partner will be transparent and give you a clear, all-in pricing sheet. A practical tip: Always ask for a sample invoice before you sign. It shows you exactly how they bill and what a typical month will look like, with no surprises.

Ready to stop overselling and streamline your fulfillment across every channel? OneCart centralizes your inventory and orders from Shopee, Lazada, TikTok Shop, and Shopify into a single, powerful dashboard. See how top brands scale their operations by visiting https://www.getonecart.com to book a demo.

Automate & Scale Your Online Business with OneCart

Start a Free TrialUsed by hundreds of merchants in Singapore & Southeast Asia